Showroom

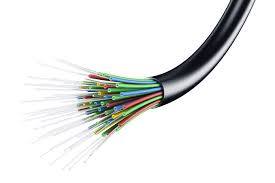

Single Mode Fiber Optic Cables are available in different diameters from 8.3 to 10 microns to meet the demands of mode of transmission. They come with relatively narrow diameter to propagate one mode only like 1310 or 1550nm.

Multi Mode Fiber Optic Cables are developed to carry multiple light rays or modes at the same time at marginally different reflection angle. They are flexible and durable cables used in different applications.

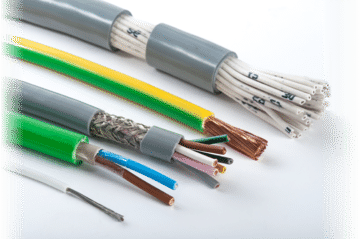

Durable and cost-effective Conductors Cables are designed using high-quality copper and other raw materials to ensure maximum conductivity, efficacy and toughness.

These lead free and environment friendly Electrical Wires are sure to provide complete safety and security during transmission of electricity in residential and commercial complexes.

Aerial Bundled Cables are overhead power lines available with insulated phase conductors bounded by a bare neutral conductor. They can easily install in close proximity to trees or buildings as they do not produce spark.

These Rubber Cables are the perfect combination of robustness and flexibility that make them ideal to be used in power supply applications to portable electrical equipments. They withstand extreme weather, thermal stresses and abrasion.

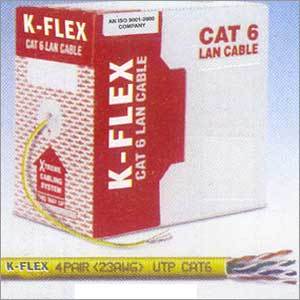

Networking Cables are widely used for connecting one network device to another or computers to printers, scanners etc. They are widely used for short or long distances in homes, offices and varied other wiring closets.

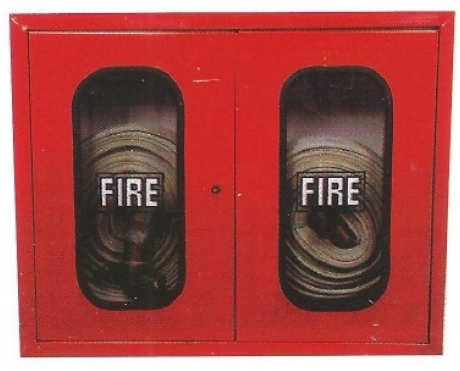

These Fire Safety Equipments are designed to protect the buildings and valuables from the hazards of fire. They are compact and light-weight products designed for easy installation and usage.

These durable and strong Cable Terminal lugs are developed using high-end raw materials for ensuring safety and quality in different electric transmission applications.

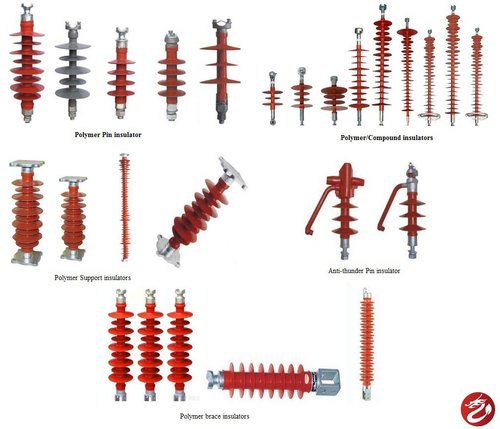

Porcelain Insulators are used for collecting electricity strain in an efficient and cost-effective way. They are available from low, medium to high voltage levels as per the demands.

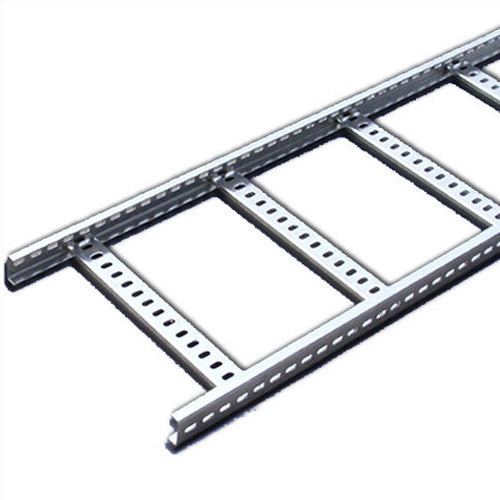

These efficient and durable Cable Trays are used to provide support to cables and full mechanical protection. They are designed to provide complete safety to the cables along with ventilation.

Ensure complete safety of the spaces with efficient transmission of signals with these unmatched Telecommunications Cables. They are ideal to provide complete safety and security of the spaces with fire-retardant features.