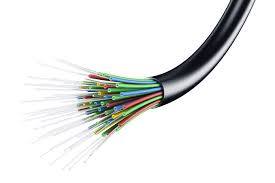

Armored Fiber Optic Cable

Price 30 INR/ Meter

Armored Fiber Optic Cable Specification

- Features

- High tensile strength, Crush resistant, Waterproof, Rodent proof, UV resistant, Superior mechanical protection

- Cable Type

- Outdoor Armored

- Armored Material

- Corrugated steel tape

- Operating Temperature

- -40C to +70C

- Diameter

- 7mm to 13mm (varies by cable spec)

- Weight

- Approximately 70-250kg/km depending on design

- Conductor Shape

- Circular

- Tensile Strength

- 1500N (short term); 600N (long term)

- Insulation

- Tight-buffered

- Install Type

- Direct burial, duct installation, aerial

- Conductor Type

- Single-mode or Multi-mode

- Number of Conductor

- 2-24 cores (customizable)

- Core Number

- 2-24 (customizable)

- Impedance

- N/A (not applicable for fiber optic cables)

- Usage & Applications

- Telecom backbone, data transmission, LAN/WAN, CATV, military field use

- Dielectiric Strength

- Not applicable for fiber cable (non-conductive)

- Core Material

- High purity silica (glass)

- Rated Temperature

- -40C to +70C

- Product Type

- Armored Fiber Optic Cable

- Length

- Customizable (standard: 1000 meters)

- Voltage

- N/A (Optical fiber is non-conductive)

- Insulation Material

- Polyethylene (PE) / High-Density Polyethylene (HDPE)

- Application

- Outdoor/Indoor, underground installation, direct burial, harsh environments, telecommunication network, data centers

- Conductor Material

- Glass fiber core

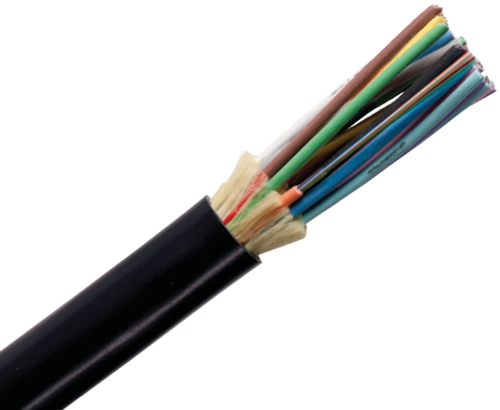

- Jacket Material

- PE/HDPE outer jacket

- Storage Temperature

- -40C to +70C

- Connector Color

- Black (as per cable jacket)

- Shield Material

- Corrugated steel tape armor

- Jacket Color

- Black

- Dimension (L*W*H)

- Customized per reel, standard length per roll: ~1000m

- Color

- Black jacket

- Material

- Glass fiber, Steel, PE/HDPE

- Size

- Outer diameter 7mm to 13mm (varies by core number)

- Attenuation

- 0.35dB/km @1310nm, 0.22dB/km @1550nm

- Crush Resistance

- 2200N/100mm

- Water Blocking Material

- Water-blocking tape and gel

- Flame Retardant

- Yes (outer sheath available in flame-retardant version)

- Outer Sheath Thickness

- 1.8mm to 2.6mm

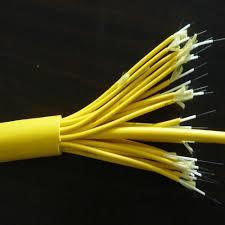

- Fiber Count

- 2, 4, 6, 8, 12, 24, or custom

- Installation Tension

- 1500N (short term), 600N (long term)

- Standards Compliance

- ISO/IEC 11801, ITU-T G.652.D, IEC 60794

- UV Resistant

- Yes

- Bending Radius

- Static 10x cable diameter, Dynamic 20x cable diameter

- Rodent Protection

- Yes (armored steel tape)

- Ripcord

- Included for easy splitting

Armored Fiber Optic Cable Trade Information

- Minimum Order Quantity

- 100 , , Meter

- Supply Ability

- 1000 Per Day

- Delivery Time

- 1 Days

About Armored Fiber Optic Cable

Armored Fiber Optic Cable is widely used for extra mechanical protection in any network. This is designed using aluminum armor wrapped around the cable to meet the demands of indoor and indoor/outdoor cables. They are the perfect combination of sturdiness, ruggedness and excellent crush resistance. With rugged design and style, it is sure to offer extra mechanical and rodent protection to the electrical wiring systems. It can be easily installed in underground buildings or the buildings with congested pathways. It ensures to reduce the risk of downtime and cable damage as it comes with abrasion-proof coating. It is available in different lengths according to the needs.Engineered for Extreme Durability

Built with armored corrugated steel tape and thick PE/HDPE jackets, this fiber optic cable stands up to direct burial, heavy crush loads, rodents, and challenging outdoor environments. Its robust structure endures tensions up to 1500N, bending stresses, UV exposure, and extreme temperatures from -40C to +70C without losing optical integrity.

Waterproof and Trouble-Resistant Design

Equipped with water-blocking tape and gel, this cable prevents moisture ingress, making it perfectly suited for underground or wet-area installations. Flame-retardant options and rodent protection allow for safe and secure deployments in a range of harsh settings, including telecommunication networks and data centers.

Flexible Fiber Counts and Customization

Choose from 2, 4, 6, 8, 12, 24 fibers or customize to your needs. Outer diameters, lengths, and mechanical specifications are adaptable, supporting unique infrastructure requirements. The included ripcord ensures rapid, clean splicing during installation.

FAQs of Armored Fiber Optic Cable:

Q: How does the armored fiber optic cable achieve superior crush resistance and mechanical protection?

A: The cable utilizes a corrugated steel tape armor layer and a thick PE/HDPE outer sheath, providing crush resistance of 2200N/100mm. This design shields the inner glass fiber cores from physical impacts and mechanical stresses during installation and operation.Q: What installation environments is the cable best suited for, and can it be used both indoors and outdoors?

A: This armored fiber optic cable is designed for versatile use, including outdoor direct burial, underground duct installations, aerial runs, and even harsh environments. Its waterproof, UV-resistant, and rodent-proof features make it equally reliable indoors or outdoors, especially in telecommunication networks and data centers.Q: When is it necessary to use the flame-retardant outer sheath version?

A: The flame-retardant sheath version is recommended for areas with elevated fire risk or specific regulatory requirements, such as building entrances, indoor installations, or spaces where fire safety compliance is crucial.Q: Where does the cable derive its water-blocking capability?

A: Water-blocking tape and gel are strategically integrated into the cables construction, effectively preventing water ingress and protecting against moistureensuring reliable long-term operation even in wet or underground settings.Q: What benefits does the cables armored, rodent-proof construction provide?

A: The corrugated steel tape armor not only prevents physical damage from rodents but also enhances mechanical durability, minimizing the risk of service interruption due to gnawing or other environmental hazards.Q: How is the cables fiber count and length customized during ordering?

A: Fiber count options include 2, 4, 6, 8, 12, or 24 cores, with further customization possible to suit specific project requirements. Standard lengths are 1000 meters per reel, but custom lengths and dimensions can be arranged upon request.Q: What is the typical installation process for this armored fiber optic cable?

A: Installation involves laying the cable directly in the ground, ducts, or aerial supports. The included ripcord allows easy sheath removal for fast splicing or termination. The cable supports static and dynamic bending as per standards, and can be pulled with tensions up to 1500N short-term, ensuring efficient deployment in various conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Single Mode Fiber Optic Cables Category

4 core fiber optic cable

Price 30 INR / Meter

Minimum Order Quantity : 100

Impedance : N/A (specific to electrical cables)

Material : Silica glass, PVC, PE

Usage & Applications : FTTH, FTTx, LAN, WAN, CCTV network deployment

Number of Conductor : 4

12 core fiber Optic cable

Price 30 INR / Meter

Minimum Order Quantity : 100

Impedance : Optical fiber, no electrical impedance

Material : Glass Fiber for core, PE/PVC for jacket

Usage & Applications : LAN/WAN Networks, Backbone, FTTH

Number of Conductor : 12

Fiber Optic Cable

Price 30 INR / Meter

Minimum Order Quantity : 100

Impedance : Not applicable (fiber optic cable is nonconductive)

Material : Glass Fiber / Plastic Fiber, PVC/LSZH Jacket

Usage & Applications : Highspeed internet, Data centers, Telecommunication links, CCTV, Military, Industrial automation

Number of Conductor : 1, 2, 4, 8, 12, 24, or custom

24 core fiber Optic cable

Price 30 INR / Meter

Minimum Order Quantity : 100

Impedance : NA (Optical)

Material : Glass, Polyethylene, HDPE

Usage & Applications : Longdistance outdoor deployment, backbone, FTTH, FTTx

Number of Conductor : 24

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free