Telecommunication Cables Jelly Filled Cables

Price 30 INR/ Meter

Telecommunication Cables Jelly Filled Cables Specification

- Armored Material

- Steel Tape (Armored type only)

- Diameter

- As per specified pair count, typically 6mm to 25mm

- Conductor Type

- Solid

- Insulation

- Foamed Polyethylene or solid PE

- Conductor Shape

- Round

- Core Number

- As per number of pairs

- Features

- Weather-resistant, robust, protection against moisture ingress via jelly filling, excellent signal transmission

- Cable Type

- Jelly Filled Telephone Cable

- Install Type

- Direct burial, aerial, duct

- Impedance

- 120 Ohms (Nominal)

- Tensile Strength

- Satisfies IS:1554 standards

- Operating Temperature

- -20C to +70C

- Weight

- Depends on pair count and length (typical 20-120 kg/km)

- Usage & Applications

- Telephone exchange, outdoor network, direct burial, duct installations

- Core Material

- Polyethylene insulated twisted pairs

- Dielectiric Strength

- 2kV/minute

- Number of Conductor

- Varies (commonly 2, 5, 10, 20, 50, 100 pairs)

- Rated Temperature

- -20C to +70C

- Product Type

- Jelly Filled Telecommunication Cable

- Length

- 100m, 305m, 500m, 1000m (custom lengths available)

- Voltage

- 300V

- Insulation Material

- High-Density Polyethylene (HDPE)

- Application

- Telecommunication, voice transmission, data communication, indoor and outdoor cabling

- Conductor Material

- Electrolytic grade solid annealed copper

- Jacket Material

- Polyethylene (PE)

- Storage Temperature

- -20C to +65C

- Shield Material

- Aluminum tape or Poly-aluminum (as specified)

- Jacket Color

- Black or as per requirement

- Dimension (L*W*H)

- Varies as per number of pairs & size; contact for details

- Material

- Copper, Polyethylene, Jelly

- Color

- Black

- Size

- 0.4mm & 0.5mm conductor diameter (common sizes)

- Minimum Bending Radius

- 15 x cable diameter

- UV Resistance

- Provided with black PE sheath for UV protection

- Moisture Resistance

- High, due to jelly filling

- Mutual Capacitance Unbalance

- 1.2 nF/km (max)

- Filling Compound

- Non-hygroscopic petroleum jelly

- Packing Type

- Wooden drums or as specified

- Capacitance

- 56 ± 5 nF/km (nominal)

- Operating Voltage

- Up to 300V

- Fire Resistance

- Self-extinguishing and flame retardant (as per standard)

- Pair Identification

- Numbered and color-coded according to standard

- RFI/EMI Performance

- Excellent immunity due to shield/jelly

Telecommunication Cables Jelly Filled Cables Trade Information

- Minimum Order Quantity

- 100 Meter

- Supply Ability

- 1000 Per Day

- Delivery Time

- 1 Days

About Telecommunication Cables Jelly Filled Cables

Superior Moisture and Weather Protection

Jelly Filled Cables utilize a specially formulated, non-hygroscopic petroleum jelly to prevent water ingress. Combined with a UV-resistant black polyethylene sheath and self-extinguishing properties, they are engineered for longevity and dependable operation in demanding outdoor environments.

Exceptional Signal Integrity and Performance

With excellent EMI/RFI immunity, low capacitance variation, and uniform impedance, these cables maintain superior signal quality. The use of solid annealed copper conductors, high-density PE insulation, and precise shielding ensures data and voice communications remain crisp and clear over long distances.

Flexible Applications and Robust Construction

Suitable for telecommunication exchanges, outdoor networks, and duct installations, these jelly-filled cables come in multiple pair counts and lengths, accommodating diverse project needs. Armored and non-armored types, backed by rigorous standards, deliver versatile reliability in critical communication infrastructure.

FAQs of Telecommunication Cables Jelly Filled Cables:

Q: How does the jelly filling enhance the cables performance?

A: The non-hygroscopic petroleum jelly used as the filling compound prevents moisture from entering the cable, effectively protecting the inner conductors from water-induced damage and oxidation. This results in long-term, reliable signal transmission, even in environments prone to dampness or water exposure.Q: What benefits do jelly filled cables offer for telecommunication installations?

A: These cables provide robust moisture resistance, excellent immunity to electromagnetic (EMI) and radio frequency (RFI) interference, and strong UV and fire resistance. This makes them ideal for outdoor, direct burial, aerial, and duct installations where environmental conditions can compromise ordinary cables.Q: When should I choose an armored version of the jelly filled cable?

A: An armored version with steel tape should be selected for installations that require extra physical protection, such as direct burial in rocky areas or locations where mechanical stress is expected. The armor significantly improves the cables durability against external impacts.Q: Where are these jelly filled cables typically used?

A: These cables are commonly used in telephone exchanges, outdoor telecommunication networks, direct burial applications, aerial pathways, and duct installations. Their rugged construction makes them suitable for both urban infrastructure and remote area deployments.Q: What is the process for identifying cable pairs during installation?

A: Each pair within the cable is both numbered and color-coded following industry standards, ensuring straightforward identification and organization during installation, maintenance, or splicing. This minimizes errors and speeds up the wiring process.Q: How is the cable protected against UV radiation and fire hazards?

A: A black polyethylene (PE) sheath offers strong UV protection for outdoor installations, while the cables construction meets fire retardant and self-extinguishing standards. This dual protection maintains cable integrity under various environmental stresses.Q: What are the standard lengths and sizes available for these cables?

A: Jelly filled telecommunication cables are available in lengths of 100m, 305m, 500m, and 1000m, with custom lengths offered as needed. Common conductor diameters include 0.4mm and 0.5mm, and pair counts range from 2 to 100 pairs, accommodating diverse installation requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Conductors Cable Category

LT PVC XLPE Power Control Cable

Price 30 INR / Meter

Minimum Order Quantity : 100

Tensile Strength : High, suitable for industrial installation

Weight : Varies with specification and core count

Operating Temperature : 10C to +90C

Usage & Applications : Industrial power control, energy distribution, outdoor and indoor control systems

Copper Single Multicore Flexible Cable

Price 30 INR / Meter

Minimum Order Quantity : 100

Tensile Strength : 15 N/mm (Insulation)

Weight : Varies as per core and length

Operating Temperature : 10C to +70C

Usage & Applications : Household, Industrial, Machinery, Control Panels

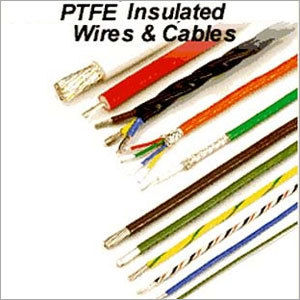

PTFE Insulated Wires & Cables

Price 30 INR / Meter

Minimum Order Quantity : 100

Tensile Strength : 200 350 N/mm

Weight : Varies with size and length

Operating Temperature : 65C to +260C

Usage & Applications : Instrumentation, High temperature environments, Labs, Switchgear, Control panels

Silicon EPR Rubber Cables

Price 30 INR / Meter

Minimum Order Quantity : 100

Tensile Strength : 12 N/mm

Weight : Varies by length, size and core count

Operating Temperature : 60C to +180C

Usage & Applications : Industrial, Power, Electrical Panels, Heaters, Chemical Plants

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS