Silicon EPR Rubber Cables

Price 30 INR/ Meter

Silicon EPR Rubber Cables Specification

- Core Material

- Tinned Copper / Bare Copper

- Insulation

- Silicon Rubber

- Usage & Applications

- Industrial, Power, Electrical Panels, Heaters, Chemical Plants

- Cable Type

- Silicon EPR Rubber Flexible Cable

- Weight

- Varies by length, size and core count

- Operating Temperature

- -60C to +180C

- Conductor Shape

- Round

- Core Number

- 1, 2, 3, Multicore

- Features

- High temperature resistance, Flexibility, Weatherproof, Resistant to oils and chemicals, Flame retardant

- Install Type

- Fixed, Flexible, Portable

- Dielectiric Strength

- 20 kV/mm

- Impedance

- Standard, varies with size

- Diameter

- Varies as per cable size

- Tensile Strength

- 12 N/mm

- Number of Conductor

- 1 Core, 2 Core, 3 Core, and Multicore options available

- Conductor Type

- Stranded / Flexible

- Armored Material

- Optional Steel Wire Armour (SWA) / Not Armored

- Rated Temperature

- -60C to +180C

- Product Type

- Silicon EPR Rubber Power Cable

- Length

- Available in custom lengths (standard rolls 100 m, customizable as per requirement)

- Voltage

- Up to 1100V

- Insulation Material

- Silicon Rubber

- Application

- Power transmission and distribution, industrial wiring, equipment wiring, heating systems, automotive

- Conductor Material

- Tinned Copper / Annealed Copper

- Jacket Material

- EPR (Ethylene Propylene Rubber)

- Storage Temperature

- -25C to +100C

- Connector Color

- Black or as per requirement

- Shield Material

- None/Optional copper braiding or tinned copper

- Jacket Color

- Red/Black/Blue/Yellow/Various colors available

- Dimension (L*W*H)

- Depends on configuration and length

- Material

- Silicon Rubber Insulated, EPR Jacketed, Copper Core

- Color

- Multiple color options

- Size

- 0.5 sqmm to 120 sqmm

- Packing Type

- Reel / Roll / Drum

- Ozone Resistance

- Yes

- Flame Resistance Standard

- Meets IEC 60332-1

- Halogen Free

- Yes

- Surface Finish

- Smooth / MATT finish

- Waterproof Grade

- IP67/IP68 (on request)

- Rated Current

- Up to 500A (depends on size)

- UV Resistance

- Yes

- RoHS Compliance

- Yes

- Sheath Thickness

- Standard 1.2mm or customized

- Minimum Bending Radius

- 6 x Cable Diameter

- Resistant to Oils and Chemicals

- Yes

Silicon EPR Rubber Cables Trade Information

- Minimum Order Quantity

- 100 Meter

- Supply Ability

- 1000 Per Day

- Delivery Time

- 1 Days

About Silicon EPR Rubber Cables

Superior Flexibility and Durability

These cables are engineered for high flexibility and resilience, accommodating fixed, portable, and flexible installations across industrial and power distribution systems. Their stranded copper cores, smooth or matt surface finish, and customizable sheath thickness provide both physical robustness and easy handling, supporting a wide range of operating temperatures.

Designed for Harsh and Hazardous Environments

With flame retardant properties, silicon EPR rubber cables are certified to IEC 60332-1 and are halogen-free, minimizing hazardous emissions during fire situations. Resistance to UV, ozone, oils, chemicals, and optional waterproofing to IP67/IP68 make them ideal for outdoor and corrosive environments, safeguarding equipment and personnel safety.

Versatile Applications and Customization

Available in single, multicore, and armored versions, with multiple color, current rating (up to 500A), and voltage options, these cables are suitable for power transmission, heaters, industrial panels, chemical plants, and automotive uses. Reel, roll, or drum packing and tailor-made lengths ensure seamless integration into diverse installation setups.

FAQs of Silicon EPR Rubber Cables:

Q: How are Silicon EPR Rubber Cables typically used in industrial settings?

A: Silicon EPR Rubber Cables are widely used for power transmission, industrial wiring, electrical panels, heating systems, and in environments where flexibility, flame resistance, and weatherproofing are essential. Their high temperature and chemical resistance make them particularly suitable for chemical plants and outdoor applications.Q: What benefits do these cables offer compared to conventional PVC cables?

A: Unlike PVC cables, Silicon EPR Rubber Cables provide superior high and low temperature performance (-60C to +180C), are flame retardant, halogen free, and resistant to UV, ozone, oils, and chemicals. This results in higher safety, durability, and reliability in demanding conditions.Q: When should customers consider IP67 or IP68 waterproof options?

A: IP67 or IP68 waterproofing should be selected when the cables will be exposed to water immersion or frequent wet conditions, ensuring continuous operation and electrical safety. These options are recommended for applications in outdoor, underground, or humid environments.Q: Where can these cables be installed and what are the color options?

A: These cables can be installed in both fixed and flexible configurations, indoors or outdoors, including hazardous areas. They are available in standard colors like red, black, blue, yellow, and can be supplied in custom colors as required for identification or specific applications.Q: How can users determine the correct cable specification for their project?

A: To select the appropriate cable, consider factors such as current and voltage rating, environmental resistance requirements, number of cores, conductor size (0.5 sqmm to 120 sqmm), flexibility, and installation conditions. Consulting with the manufacturer or supplier can ensure an optimal match for your application.Q: What is the process for ordering customized lengths or features?

A: Customers can order cables in standard 100m rolls or specify custom lengths and variations such as sheath thickness, armor, color, and number of cores. Simply provide your requirements to the distributor, exporter, manufacturer, or supplier for a tailored solution.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Conductors Cable Category

LT PVC XLPE Power Control Cable

Price 30 INR / Meter

Minimum Order Quantity : 100

Dielectiric Strength : 3.5 kV for 5 minutes

Storage Temperature : 20C to +60C

Length : Available in standard and custom lengths up to 1000 meters

Insulation Material : Other, PVC/XLPE

Copper Single Multicore Flexible Cable

Price 30 INR / Meter

Minimum Order Quantity : 100

Dielectiric Strength : 2000V AC for 1 minute

Storage Temperature : 10C to +60C

Length : Available up to 500 meters or as specified

Insulation Material : PVC

Shielded Instrumentation Cable

Price 30 INR / Meter

Minimum Order Quantity : 100

Dielectiric Strength : 2 kV for 1 minute

Storage Temperature : 30C to +75C

Length : 100 meters (Custom lengths available)

Insulation Material : Other, PVC (Polyvinyl Chloride)

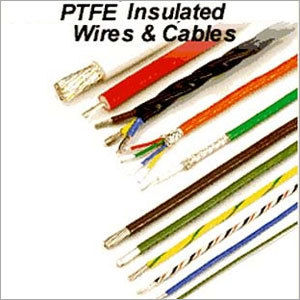

PTFE Insulated Wires & Cables

Price 30 INR / Meter

Minimum Order Quantity : 100

Dielectiric Strength : 15 KV/mm

Storage Temperature : Up to 260C

Length : Available in standard and customized lengths (1m, 10m, 100m, etc.)

Insulation Material : Other, PTFE (Polytetrafluoroethylene)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS