Silicon Rubber Cables

Price 30 INR/ Meter

Silicon Rubber Cables Specification

- Locking Type

- Not Applicable for cable

- Core Number

- 1, 2, 3, 4, 5, or Multicore

- Weight

- Varies per size and length

- Usage & Applications

- High/Low temperature environment, Medical, Power Cable, Electric Panel Wiring, Lighting, Automotive, Defence

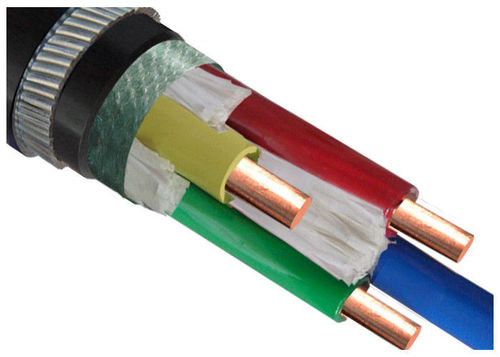

- Conductor Type

- Stranded or Solid (as per requirement)

- Core Material

- Copper

- Armored Material

- Optional: Steel Wire Armour

- Tensile Strength

- Extremely high (as per IS/IEC norms)

- Number of Conductor

- Single core, Multicore available

- Cable Type

- Flexible, Multicore or Single Core

- Conductor Shape

- Round

- Install Type

- Indoor and outdoor, fixed or flexible installation

- Insulation

- High-grade Silicone Rubber

- Impedance

- Varies as per cable construction (typically 5075 ohms for RF types)

- Diameter

- As per customer choice and cable specification

- Dielectiric Strength

- Minimum 1.5 kV AC for 1 minute

- Rated Temperature

- -60C to +180C (short period up to 200C)

- Features

- High flexibility, Heat resistance, Flame retardant, Ozone and weather resistance, Excellent electrical properties, Non-toxic, Suitable for high and low temperature applications

- Operating Temperature

- -60C to +180C

- Product Type

- Silicon Rubber Cable

- Length

- Customized (standard available 100 meters roll)

- Voltage

- Up to 1100 V

- Insulation Material

- Silicone Rubber

- Application

- Electrical and electronic equipment, Industrial machinery, Power supply, Control panels, Household appliances, Medical devices

- Conductor Material

- High conductivity Copper

- Jacket Material

- Silicone Rubber

- Storage Temperature

- -20C to +80C

- Connector Color

- Red, Black, Blue, White, Yellow (customized on request)

- Shield Material

- Optional Tinned Copper Braid (for shielded types)

- Jacket Color

- Red, Black, Blue, White, Yellow, Green (as per requirement)

- Dimension (L*W*H)

- Varies as per cable size; refer to cable data sheet

- Color

- Red, Black, Blue, White, Yellow, Green

- Material

- Silicone Rubber insulated copper cable

- Size

- 0.5 sqmm to 50 sqmm (custom sizes available)

- Halogen Free

- Yes, non-toxic and halogen-free

- Oil Resistance

- Good (resists most industrial oils and greases)

- Surface Finish

- Smooth, abrasion resistant

- Minimum Bending Radius

- 6 x Overall Diameter (approximate)

- Flame Retardance

- Passes IEC 60332/UL 94 V-0 flame test

- Elongation at Break

- >250% (typical for insulation)

- UV Resistance

- Excellent resistance to ultraviolet radiation

- Capacitance

- Varies as per construction; consult data sheet

- Dielectric Constant

- 2.93.5 at 1 kHz

Silicon Rubber Cables Trade Information

- Minimum Order Quantity

- 100 Meter

- Supply Ability

- 1000 Per Day

- Delivery Time

- 1 Days

About Silicon Rubber Cables

Putting quality above quantity, our organization is enthusiastically engaged in offering Silicone Rubber Cable. This cable is designed and developed using superior quality rubber that is obtained from reliable vendors of the market. To ensure flawless finish, this cable is thoroughly checked on various set parameters like strength by a team of quality controllers. Our provided cable is widely used in various commercial and engineering industries. We assure to deliver this Silicone Rubber Cable in different specifications as per the preferences of clients.

Outstanding Flame Retardance and Safety

Designed to withstand the most stringent flame tests (IEC 60332/UL 94 V-0), these silicone rubber cables enhance operational safety by minimizing fire risks. Their halogen-free composition ensures non-toxic emissions, protecting both people and equipment during emergencies.

Broad Application Versatility

These cables are engineered for use across varied environments, from industrial machinery and medical devices to household appliances and outdoor installations. Their consistent flexibility, weather resistance, and customizable configurations make them adaptable for both fixed and flexible wiring needs.

Superior Electrical and Mechanical Performance

With outstanding electrical properties, exceptional tensile strength, and abrasion resistance, these cables maintain high functionality in challenging conditions. Their surface finish and construction mitigate wear, while optional armoring provides added mechanical protection when required.

FAQs of Silicon Rubber Cables:

Q: How do silicon rubber cables provide flame retardance and safety?

A: Silicon rubber cables are manufactured to pass IEC 60332/UL 94 V-0 flame retardance standards, ensuring they self-extinguish and do not propagate fire. Their halogen-free, non-toxic composition further prevents hazardous gas release during a fire, providing enhanced safety in sensitive settings.Q: What are the primary applications and industries for these cables?

A: These cables are commonly used in electrical and electronic equipment, industrial machinery, control panels, power supplies, medical devices, household appliances, and automotive wiring. Their adaptability makes them ideal for environments requiring high flexibility, heat resistance, and reliable insulation properties.Q: When should I choose silicon rubber cables over standard PVC cables?

A: Choose silicon rubber cables when your installation will be exposed to extreme temperatures, UV radiation, oil, or environments where flame retardance and non-toxicity are critical. Applications demanding long service life, flexibility, and superior electrical insulation also benefit from silicone rubber cables.Q: Where can these cables be installed effectively?

A: Silicon rubber cables can be installed both indoors and outdoors, and are suitable for fixed or flexible wiring. Their robust construction ensures performance in high/low temperature locations, harsh industrial settings, as well as in environments exposed to sunlight and weathering.Q: What is the typical process for selecting the right cable configuration?

A: The selection process involves determining core count, cross-sectional area (0.5 sqmm to 50 sqmm or custom sizes), color, length, and whether shielding or armoring is needed. Refer to the cables data sheet for property specifics, and consult the supplier or manufacturer for tailored solutions.Q: How do these cables benefit long-term operational reliability?

A: These cables provide durable performance under continuous flexing, resist abrasion and industrial oils, and maintain electrical properties across a wide temperature range, reducing downtime and replacement needs. Their mechanical and dielectric strength ensure longevity in mission-critical applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber Cables Category

Epr Rubber Cable

Price 30 INR / Meter

Minimum Order Quantity : 100

Cable Type : Flexible rubber cable

Material : Ethylene Propylene Rubber, Copper

Conductor Material : Other, High conductivity copper

Conductor Shape : Round

Copper Pvc Armoured Cables

Price 30 INR / Meter

Minimum Order Quantity : 100

Cable Type : Armoured Copper Power/Control Cable

Material : Copper conductor, PVC insulation, steel armouring, PVC sheath

Conductor Material : Other, High purity annealed copper

Conductor Shape : Other, Round, stranded or solid

Pvc Insulated Armoured Power Cable

Price 30 INR / Meter

Minimum Order Quantity : 100

Cable Type : Armoured

Material : Copper/Aluminum, PVC, Galvanized Steel

Conductor Material : Other, Copper / Aluminum

Conductor Shape : Round

Aluminium Unarmoured Xlpe Insulated Cables

Price 30 INR / Meter

Minimum Order Quantity : 100

Cable Type : Unarmoured Power Cable

Material : Aluminium with XLPE insulation and PVC sheath

Conductor Material : Other, Aluminium

Conductor Shape : Other, Round/sector shaped

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS