Epr Rubber Cable

Price 30 INR/ Meter

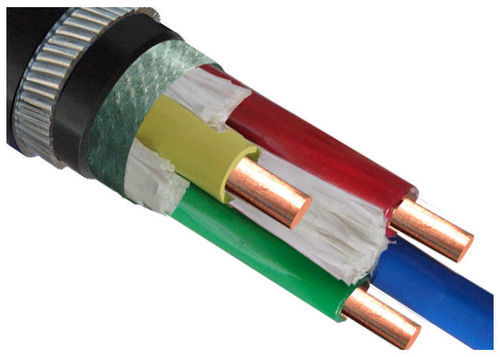

Epr Rubber Cable Specification

- Core Number

- 2, 3, 4 or 5

- Core Material

- Copper

- Rated Temperature

- -25C to 90C

- Conductor Type

- Stranded

- Diameter

- As per customer specification

- Number of Conductor

- 2 core, 3 core, 4 core, 5 core (as per requirement)

- Weight

- Variable as per size and length

- Install Type

- Indoor and outdoor installation

- Locking Type

- Non-locking

- Armored Material

- Steel wire armoured (optional)

- Features

- High flexibility, heat resistant, oil resistant, weather resistant, flame retardant, durable insulation, outstanding mechanical strength

- Usage & Applications

- Suitable for power transmission in harsh and flexible working environments

- Insulation

- EPR Ethylene Propylene Rubber

- Impedance

- Standard (as per IEC/IS standards)

- Operating Temperature

- -25C to 90C

- Dielectiric Strength

- 2.5 kV for 15 min

- Cable Type

- Flexible rubber cable

- Conductor Shape

- Round

- Tensile Strength

- >15 N/mm

- Product Type

- Flexible EPR Rubber Cable

- Length

- 100 meters (custom lengths available)

- Voltage

- up to 1100 V

- Insulation Material

- EPR (Ethylene Propylene Rubber)

- Application

- Industrial, mining, power transmission, heavy machinery, welding, submersible pumps

- Conductor Material

- High conductivity copper

- Jacket Material

- Flexible rubber

- Storage Temperature

- -30C to 70C

- Connector Color

- Black

- Shield Material

- Copper braiding (optional)

- Jacket Color

- Black

- Dimension (L*W*H)

- Varies as per cable size

- Color

- Black

- Material

- Ethylene Propylene Rubber, Copper

- Size

- 1.5 sq.mm to 240 sq.mm

- Inner Sheath Material

- Rubber compound

- UV Resistance

- Superior, suitable for direct sunlight

- Water Resistance

- Highly resistant, suitable for outdoor use

- Packaging

- Coil/Drum Packing

- Halogen Free

- Yes, on request

- Ozone Resistance

- Excellent

- Minimum Bending Radius

- 6 x overall diameter

- Ambient Temperature Range

- -30°C to +90°C (Fixed), up to 80°C (Flexing)

- Fire Resistance

- Yes, flame retardant as per IEC standards

- RoHS Compliance

- Yes

- Voltage Grade

- 450/750 V, 0.6/1kV

- Moisture Resistance

- High

- Surface Finish

- Smooth and abrasion resistant

- Cable Standard

- Conforms to IS/IEC standards

Epr Rubber Cable Trade Information

- Minimum Order Quantity

- 100 Meter

- Supply Ability

- 1000 Per Day

- Delivery Time

- 1 Days

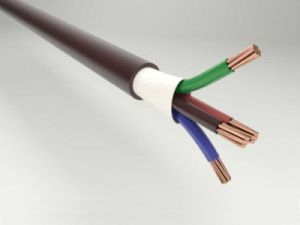

About Epr Rubber Cable

With our strong commitment to deliver qualitative products to our customers, we are able to provide a reliable range of EPR Rubber Cable. These cables are manufactured in accordance with the international quality standards and the current market trends. Highest grade materials like annealed tinned copper and heat resisting elastomer is used in the manufacturing process to to make sure that the cables offered by us are of superior quality. Our EPR Rubber Cable is widely demanded by our clients as it is compatible with most extreme conditions.

Reliable Performance in Extreme Conditions

Engineered for both indoor and outdoor environments, EPR Rubber Cable endures severe weather, UV exposure, moisture, and abrasion. Its robust rubber sheath and EPR insulation deliver unwavering electrical and mechanical performance, making it ideal for industrial, mining, or outdoor applications requiring maximum reliability.

Flexible Solutions for Versatile Applications

This cables flexible design and wide size range (1.5 sq.mm to 240 sq.mm) ensure easy installation, even in tight or complex spaces. With multiple core options (2 to 5), stranded copper conductors, and optional armouring and shielding, it adapts to diverse power transmission, heavy machinery, and submersible pump needs.

Enhanced Safety and Compliance

EPR Rubber Cable is flame retardant per IEC standards, RoHS compliant, and optionally halogen-free. Its high dielectric strength (2.5 kV for 15 min) and abrasion-resistant smooth finish guard against hazards while ensuring compliance with IS/IEC norms, making it a secure and dependable choice for critical electrical systems.

FAQs of Epr Rubber Cable:

Q: How does EPR Rubber Cable provide fire resistance and safety in hazardous environments?

A: EPR Rubber Cable is designed as flame retardant according to IEC standards, reducing fire risks significantly. Its high dielectric strength and robust insulation further enhance safety by minimizing the risk of electrical breakdowns and protecting critical systems in hazardous environments.Q: What are the main benefits of using EPR Rubber Cable for outdoor installations?

A: This cable offers exceptional resistance against UV rays, ozone, water, and abrasion. Its flexible yet durable rubber jacket ensures long-lasting performance under direct sunlight, heavy rain, or harsh weather conditions, making it ideal for outdoor power transmission and installations.Q: Where can EPR Rubber Cable be installed and what types of applications is it suitable for?

A: EPR Rubber Cable is suitable for both indoor and outdoor installations, including industrial, mining, heavy machinery, power transmission, welding, and submersible pumps. Its robust construction allows use in environments with mechanical stress, chemical exposure, or continuous flexing.Q: What is the process for selecting the appropriate size and configuration for an EPR Rubber Cable?

A: Selection depends on application requirements such as current rating, voltage, installation type, and environmental factors. Available in sizes from 1.5 sq.mm to 240 sq.mm with options for 2, 3, 4, or 5 cores, and features like armouring or shielding can be added as needed. Custom lengths and diameters are also available.Q: How does the cables construction enhance its durability and conductivity?

A: EPR Rubber Cable features high-conductivity stranded copper conductors encased in durable EPR insulation and a tough rubber jacket. Optional copper braiding and steel wire armour further enhance mechanical strength, flexibility, and current-carrying capacity, ensuring reliable and efficient power transmission.Q: When should a halogen-free version of EPR Rubber Cable be chosen?

A: A halogen-free option is recommended for environments where low smoke and non-toxic emissions are vital, such as public spaces, underground locations, or confined industrial sites. This minimizes health risks during fire incidents while maintaining all other cable benefits.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber Cables Category

Copper Pvc Armoured Power Cables

Price 30 INR / Meter

Minimum Order Quantity : 100

Features : High conductivity, Superior mechanical protection, Flame retardant, Resistant to moisture and chemicals, Durable, Low signal loss

Insulation : PVC Type A as per IS:5831

Dimension (L*W*H) : Varies with core & size

Color : Black

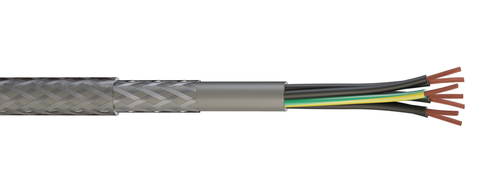

pvc armoured control cable

Price 30 INR / Meter

Minimum Order Quantity : 100

Features : Flame Retardant, Weather Resistant, High Dielectric Strength, Durable Construction, Moisture Proof, UV Resistant, Armoured Protection

Insulation : PVC Insulated

Dimension (L*W*H) : Custom as per cable size

Color : Black/ Grey

Flame Retardant Welding Cable

Price 30 INR / Meter

Minimum Order Quantity : 100

Features : Flame Retardant, High Flexibility, Durable, Oil and Abrasion Resistant

Insulation : PVC Flame Retardant

Dimension (L*W*H) : Depends on cable size and length

Color : Black

Halogen Free Flame Retardant Cable

Price 30 INR / Meter

Minimum Order Quantity : 100

Features : Halogen Free, Flame Retardant, Low Smoke, NonToxic, Ecofriendly

Insulation : Halogen Free Thermoplastic

Dimension (L*W*H) : Standard Cable Dimensions (customizable on request)

Color : Green (other colors on request)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS