frls cables

Price 30 INR/ Meter

frls cables Specification

- Number of Conductor

- Single Core / Multi Core

- Conductor Shape

- Circular/Annular

- Operating Temperature

- -5C to +70C

- Usage & Applications

- General Electrical Wiring, Underground, Internal Wiring in Conduits, Power & Control Cables

- Rated Temperature

- 70C (standard), up to 85C for select variants

- Cable Type

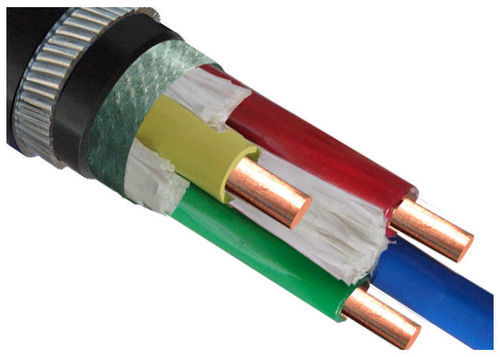

- Single Core / Multi Core, Armoured / Unarmoured

- Features

- Flame Retardant Low Smoke, Non-toxic, Halogen Free, High Flexibility, Heat Resistant, High Insulation Resistance, UV Resistant, Flexible, Moisture Resistant, Anti-Termite

- Install Type

- Indoor/Outdoor, Surface/Concealed, Underground

- Insulation

- FRLS PVC

- Impedance

- Dependent on size; consult data sheet

- Dielectiric Strength

- 3.5 kV for 5 Min

- Core Number

- 1 to 4 (common range)

- Tensile Strength

- Min. 12.5 N/mm (for Copper)

- Diameter

- Varies as per cable size

- Core Material

- Copper

- Conductor Type

- Solid/Stranded

- Armored Material

- Optional GI Steel Strip/Wire

- Weight

- Depends on size and length

- Product Type

- FRLS Electric Power & Control Cable

- Length

- 90 m roll (standard); custom length on request

- Voltage

- Up to 1100 V

- Insulation Material

- FRLS (Flame Retardant Low Smoke) PVC Compound

- Application

- Commercial, Residential, Industrial Wiring, Power Distribution, Control Panels, Lighting Circuits

- Conductor Material

- 99.97% Pure Electrolytic Grade Copper

- Jacket Material

- PVC

- Storage Temperature

- -15C to +70C

- Connector Color

- NA (custom on request)

- Shield Material

- NA / Optional Aluminum Mylar Shield (for special applications)

- Jacket Color

- Red, Yellow, Blue, Black, Green, White, Grey, Custom on request

- Dimension (L*W*H)

- Varies with cable size and type

- Color

- Red, Yellow, Blue, Black, Green, White, Grey

- Material

- Copper, FRLS PVC Compound

- Size

- 0.5 sq mm to 400 sq mm

- Flammability Test

- Passed vertical flame test as per IS:10810 Part 53

- Acid Gas Emission

- Less than 0.5% as per IEC 60754-1

- Surface Printing

- Meter marked with brand, IS/IEC code, size, voltage

- Fire Survival Time

- Up to 3 hours at 650°C in some variants

- Ambient Temperature Range

- -15°C to +55°C

- Smoke Density

- Less than 60% as per ASTM D 2843

- Packaging Type

- Coil, Drum, Roll

- Short Circuit Temperature

- Up to 160°C (for 5 seconds)

- Ozone Resistance

- Yes

- Halogen Content

- < 0.5% as per IS 694

- Conductor Class

- Class 2 or higher as per IS:8130.

- RoHS Compliant

- Yes

- Compliance Standards

- IS 694 : 2010, RoHS, IEC 60332-1

- Minimum Bending Radius

- 12 x Overall Diameter (for multi-core cables)

- Insulation Resistance

- Min. 1 G Ohm/Km at 90°C

frls cables Trade Information

- Minimum Order Quantity

- 100 Meter

- Supply Ability

- 1000 Per Day

- Delivery Time

- 1 Days

About frls cables

Being one of the leading entities, we are able to offer top notch quality FRLS cables. These cables are manufactured in our well setup infrastructure facility by making use of advanced machines and progressive techniques. The cables are covered with FRLS materials, which is known for its high resistance to heat and flame. Because of its excellent low smoke property, these cables are widely used for wiring machines and buildings. To meet the requirements of our clients, we offer these FRLS cables at market leading prices.

Uncompromised Fire Safety and Compliance

Our FRLS cables are rigorously tested to meet international and national safety standards, including IS 694:2010, IEC 60332-1, and RoHS. They excel in vertical flame tests and exhibit reduced smoke (less than 60% by ASTM D 2843) and low halogen and acid gas emissions, enhancing protection for both people and equipment in case of fire.

Versatile Design and Application

Whether you require single-core or multi-core, armored or unarmored cables, our FRLS range accommodates diverse requirements across commercial, residential, and industrial wiring projects. These cables demonstrate exceptional safety, flexibility, and durability in environments ranging from underground conduits to control panels and power distribution boards.

Enhanced Durability for All Environments

Built to withstand temperatures from -15C to +55C (up to 160C for short circuits), these cables offer high insulation resistance, ozone and UV protection, and anti-termite properties. The robust FRLS PVC compound and pure copper construction ensure long-term reliability, even in tough installation scenarios, both indoors and outdoors.

FAQs of frls cables:

Q: How do FRLS cables enhance fire safety in electrical installations?

A: FRLS cables are designed to inhibit the spread of fire due to their Flame Retardant Low Smoke (FRLS) insulation, which minimizes flame propagation, reduces the density of emitted smoke (less than 60% by ASTM D 2843), and limits both halogen and acid gas emissions. This combination helps ensure safer evacuation and reduced damage to valuable equipment during a fire event.Q: What compliance standards do these FRLS cables meet?

A: Our FRLS cables conform to major safety and quality benchmarks, including IS 694:2010, IEC 60332-1 (vertical flame test), RoHS, ASTM D 2843 (smoke density), IEC 60754-1 (acid gas emission), and IS:10810 Part 53 (flammability). This multi-standard compliance guarantees consistent and reliable performance in critical installations.Q: When should FRLS cables be used instead of conventional cables?

A: FRLS cables are recommended in areas where fire safety is paramount, such as public buildings, commercial complexes, high-rises, hospitals, industrial plants, and data centers. Their use is ideal for internal wiring, power distribution, underground cabling, and control panels, helping to mitigate fire risks and meet regulatory requirements.Q: Where can these FRLS cables be installed?

A: These cables are suitable for indoor and outdoor usage, concealed or surface installations, and underground layouts. They are adaptable for installation in conduits, trays, or direct burial, making them ideal for a wide range of electrical and control applications in commercial, residential, and industrial infrastructures.Q: What is the process for selecting the correct FRLS cable size and variant?

A: Cable selection depends on factors like voltage rating, current capacity, installation environment, and mechanical protection needs. Refer to the product data sheet for impedance, conductor size (0.5 to 400 sq mm), and core number (1 to 4). Our team can help you determine the appropriate configuration for your specific requirements.Q: How does the construction benefit long-term cable performance?

A: Each cable is constructed using 99.97% pure electrolytic grade copper and robust FRLS PVC insulation, providing high insulation resistance (minimum 1 G Ohm/Km at 90C), flexibility, and resilience against heat, UV exposure, moisture, and termites. This ensures excellent electrical properties and durability throughout their operational lifespan.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber Cables Category

Silicon Rubber Cables

Price 30 INR / Meter

Minimum Order Quantity : 100

Core Number : 1, 2, 3, 4, 5, or Multicore

Dielectiric Strength : Minimum 1.5 kV AC for 1 minute

Material : Silicone Rubber insulated copper cable

Conductor Material : Other, High conductivity Copper

Epr Rubber Cable

Price 30 INR / Meter

Minimum Order Quantity : 100

Core Number : 2, 3, 4 or 5

Dielectiric Strength : 2.5 kV for 15 min

Material : Ethylene Propylene Rubber, Copper

Conductor Material : Other, High conductivity copper

Trs Rubber Cable

Price 30 INR / Meter

Minimum Order Quantity : 100

Core Number : 2 to 4

Dielectiric Strength : 2.5 kV

Material : Rubber and Copper

Conductor Material : Copper

Copper Pvc Armoured Power Cables

Price 30 INR / Meter

Minimum Order Quantity : 100

Core Number : 1 to 4 core

Dielectiric Strength : 3.5 kV for 5 minutes

Material : Copper, PVC, Steel (Armour)

Conductor Material : Other, High purity Annealed Copper

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS