Halogen Free Flame Retardant Wire

Price 30 INR/ Meter

Halogen Free Flame Retardant Wire Specification

- Operating Temperature

- -30C to +70C

- Conductor Type

- Single, Stranded

- Rated Temperature

- -30C to +70C

- Number of Conductor

- Single or Multi-core options

- Usage & Applications

- Suitable for fire-prone areas, public buildings, tunnels, airports, railways, hospitals, hotels, data centers

- Core Number

- 1 to multi-core

- Armored Material

- N/A (normally unarmored but available on request)

- Weight

- Depends on size and length

- Tensile Strength

- Meets IS/IEC 60332-1/3 (as per standards)

- Insulation

- Halogen Free Compound, flame retardant

- Impedance

- N/A (Applies to signal cables)

- Dielectiric Strength

- 2.5 kV for 1 min

- Cable Type

- Single-core and multi-core, LSHF (Low Smoke Halogen Free)

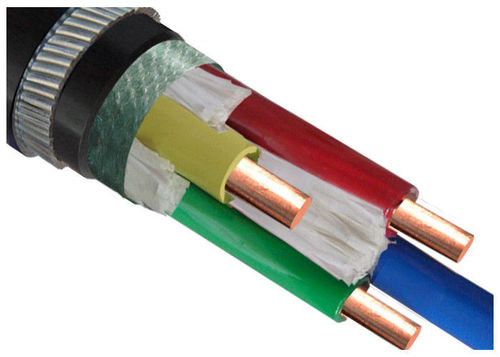

- Core Material

- Electrolytic Copper

- Features

- Halogen free, Flame retardant, Low smoke emission, Environment-friendly, Non-toxic during combustion, Excellent electrical and mechanical properties

- Conductor Shape

- Round

- Diameter

- Varies as per cable size

- Install Type

- Concealed, surface, duct, or conduit installation

- Product Type

- Halogen Free Flame Retardant Cable

- Length

- Customizable (as per requirement)

- Voltage

- 300/500V (typical)

- Insulation Material

- Halogen Free Compound (HFFR)

- Application

- Building wiring, Industrial wiring, Public places, Commercial complexes, Metro stations, Airports, Data centers

- Conductor Material

- Copper (Annealed Electrolytic grade)

- Jacket Material

- Halogen Free Compound

- Storage Temperature

- -10C to +60C

- Jacket Color

- Varies (Red, Blue, Green, Black, Yellow, White, as required)

- Dimension (L*W*H)

- Custom/Varies by size

- Color

- Available in various colors

- Material

- Copper (conductor), Halogen Free Compound (insulation and jacket)

- Size

- 0.5 sqmm - 630 sqmm (typical range)

- Package Type

- Coil, Drum, or as specified

- Conductor Class

- Class 1/2 as per IS:8130

- Halogen Emission

- < 0.5% as per IEC 60754-1

- Flammability Standard

- Meets IEC 60332-1, IS 694:2010, RoHS compliant

- Water Absorption

- < 0.1% (tested as per IEC standards)

- Minimum Bending Radius

- 8 x cable diameter (approx.)

- UV Resistance

- Available on request for outdoor installations

- Ozone Resistance

- Yes, insulation resists ozone attack

- Oil Resistance

- Available with special compound on request

- Smoke Density

- Meets IEC 61034 standards, emits less than 60% smoke

- Acid Gas Emission

- Less than 0.5%, tested as per IEC 60754-2

- Fire Resistance

- Tested as per IEC 60331 (on request)

Halogen Free Flame Retardant Wire Trade Information

- Minimum Order Quantity

- 100 Meter

- Supply Ability

- 1000 Per Day

- Delivery Time

- 1 Days

About Halogen Free Flame Retardant Wire

We are into the business of offering an excellent quality range of Halogen Free Flame Retardant Wire which is manufactured at our high profile manufacturing unit under the supervision of experienced professionals. This wire is made using specially formulated insulating material incorporating the most advance polymer technology. Our provided Halogen Free Flame Retardant Wire does not emit highly corrosive halogen gases and toxic fumes and is almost smoke free. Applications of this wire is found in fire alarm, lift, corridor and stairway lighting functional for facilitating quick escape, fire fighting and rescue operations

Compliant with International Fire Safety Standards

Engineered to meet the IEC 60332-1 and IS 694:2010 flammability standards, this wire ensures maximum safety in fire-prone environments. It also meets IEC 61034 smoke density norms, emitting less than 60% smoke, and restricts halogen and acid gas emissions to below 0.5%. These features make it ideal for buildings subject to strict regulatory requirements and public safety codes.

Superior Environmental and Health Protection

Utilizing a halogen-free compound for both insulation and jacket, this wire is environment-friendly and reduces toxic fumes during combustion. It aligns with RoHS directives, ensuring negligible environmental and occupational health risks. Its construction curtails water absorption, shielding installations from moisture-related damage.

Customizable for Diverse Applications

Available in a typical size range from 0.5 sqmm to 630 sqmm, and customizable in length, color, core number, and packaging type, the wire adapts to varied installation needs. From concealed and duct installations to surface or conduit placements, it supports versatile wiring solutions for commercial, industrial, and public infrastructure projects.

FAQs of Halogen Free Flame Retardant Wire:

Q: How does halogen-free flame retardant wire enhance safety in fire-prone environments?

A: This wire drastically reduces the release of toxic gases and smoke during combustion by employing halogen-free flame retardant insulation. It emits less than 60% smoke and below 0.5% acid gases, meeting IEC 61034 and IEC 60754-2 standards, thus protecting occupants and minimizing evacuation risks.Q: What is the recommended usage and installation process for this wire?

A: Halogen-free flame retardant wire is suitable for concealed, surface, duct, or conduit installation in buildings, airports, data centers, hospitals, tunnels, and other public or industrial places. It can be installed as single-core or multi-core cable, following the minimum bending radius guideline of 8 times the cable diameter.Q: When should you choose halogen-free wire over conventional options?

A: Opt for halogen-free wire in areas requiring stringent fire safety, such as public places, data centers, metro stations, and tunnel environments where low toxic emissions and reliable electrical performance are vital for compliance and occupant protection.Q: Where is UV and oil resistance available in these wires?

A: UV resistance is available on request for outdoor installations, ensuring durability during sun exposure. Oil resistance, provided via a special compound, is also offered upon request to suit industrial environments exposed to oils and chemicals.Q: What is the process for customizing wire specifications such as length, color, and core number?

A: Wire specifications including length, cable color, core count, and packaging can be tailored to project-specific requirements when ordering directly from the manufacturer, distributor, or supplier, ensuring seamless integration into any installation scenario.Q: What are the benefits of using this wire in commercial and public infrastructure projects?

A: Utilizing halogen-free flame retardant wire provides enhanced fire safety, reduces health hazards in case of fire, and meets international standards. Its customizable features and robust performance make it exceptionally well-suited for large-scale commercial, public, and industrial wiring projects.Q: How does the wires environment-friendly design aid in sustainable development?

A: The wire is constructed according to RoHS standards, using non-toxic materials that do not emit harmful halogen compounds during combustion. This ensures a lower environmental impact and aligns with modern sustainable building practices.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber Cables Category

Durable Pvc Armoured Power Cables

Price 30 INR / Meter

Minimum Order Quantity : 100

Cable Type : Armoured Power Cable

Voltage : Other, Up to 1100V

Material : Copper or Aluminium conductor, PVC insulation and sheathing, steel armouring

Jacket Material : PVC

Copper Pvc Armoured Cables

Price 30 INR / Meter

Minimum Order Quantity : 100

Cable Type : Armoured Copper Power/Control Cable

Voltage : Other, Up to 1100V (1.1kV) grade.

Material : Copper conductor, PVC insulation, steel armouring, PVC sheath

Jacket Material : PVC

Aluminium Armoured Cable

Price 30 INR / Meter

Minimum Order Quantity : 100

Cable Type : Armoured cable

Voltage : Other, Up to 1100 V

Material : Highgrade Aluminium, PVC insulation, armoured layer

Jacket Material : PVC

Pvc Xlpe Insulated Cable

Price 30 INR / Meter

Minimum Order Quantity : 100

Cable Type : Low/Medium Voltage Power Cable

Voltage : Other, Up to 1100V (as per IS 70981)

Material : PVC, XLPE, Copper/Aluminum

Jacket Material : Other, PVC (Polyvinyl Chloride)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free