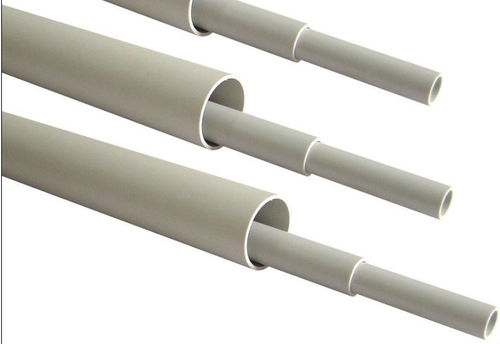

GI Conduit Pipe

Price 50 INR/ Meter

GI Conduit Pipe Specification

- Flexibility

- Rigid

- Bend Radius

- Permissible Cold Bend as per Standard

- Connection Type

- Threaded / Coupled / Plain End

- Thread Type

- BSP / NPT (as required)

- Tensile Strength

- 300400 MPa

- Yield Strength

- Min 240 MPa

- Diameter

- 2050 mm

- Temperature Range

- -10C to +60C

- Tolerance

- 0.5 mm

- Coating Type

- Zinc Coated (Galvanized)

- Product Type

- GI Conduit Pipe

- Material

- Galvanized Iron (GI)

- Connection

- Screwed / Plain Ends

- Shape

- Round

- Standard

- IS 9537 / BS 4568

- Surface Treatment

- Hot Dip Galvanized / Pre-Galvanized

- Outer Diameter

- 20 mm, 25 mm, 32 mm, 40 mm, 50 mm

- Section Shape

- Circular

- Length

- 3 meters / 3.75 meters / 4 meters

- Thickness

- 1.0 mm to 2.0 mm

- Color

- Silver / Metallic

- Usage

- Electrical Wiring Protection

- Application

- Electrical Installation / Cable Management

- Material Grade

- IS 277 / IS 513

- Installation Method

- Surface/Concealed/Trunking

- Corrosion Resistance

- High (due to Galvanization)

- Weight per Meter

- Varies by size (Approx. 2.105.50 kg/m)

- Fire Resistance

- Non-Combustible

- Packing Type

- Bundles with End Caps

GI Conduit Pipe Trade Information

- Minimum Order Quantity

- 100 Meter

- Supply Ability

- 1000 Per Day

- Delivery Time

- 1 Days

About GI Conduit Pipe

We are one of most influential entity engaged in offering a broad spectrum of GI Conduit Pipes. These pipes are manufactured using best quality metal to ensure their high tensile strength and durability. Provided pipes are widely used in various areas such as agriculture, gas, power industry and sanitary. Our ISI marked GI Conduit Pipes are praised by our clients for their excellent tensile strength, easy of jointing, less installation time and optimum resistance against fire & corrosion.

Robust and Fire-Resistant Electrical Protection

These GI Conduit Pipes provide strong, rigid, and non-combustible protection for all types of electrical installations. Engineered for both surface and concealed mounting, they ensure cable safety in residential, commercial, and industrial settings. Galvanization enhances their durability, shielding them from rust and harsh environmental conditions.

Versatility in Application and Installation

Available in a variety of diameters, thicknesses, and connection types, these pipes are suitable for numerous cable management and electrical wiring tasks. Their adaptability allows installation through trunking, coupled, or plain end connections, meeting both local and international standards required for safety and reliability.

Reliable Performance Across Conditions

With a tensile strength of 300400 MPa, these pipes can withstand mechanical stress and bending while maintaining structural integrity. Their high-quality zinc coating extends their lifespan, and bundled packaging with end caps keeps conduits pristine from production site to installation environment.

FAQs of GI Conduit Pipe:

Q: How are GI Conduit Pipes with fire resistance typically installed?

A: GI Conduit Pipes can be installed using surface, concealed, or trunking methods. They are suitable for threaded, coupled, or plain end connections, allowing flexibility based on specific project requirements and standards.Q: What benefits does the galvanized coating provide to these pipes?

A: The zinc coating obtained through hot dip or pre-galvanization greatly enhances corrosion resistance, protecting the conduit pipes from rust, moisture, and chemical exposure. This extends the service life of the pipes, even in challenging environments.Q: When should these GI Conduit Pipes be used in electrical installations?

A: These conduit pipes are ideal for projects where fire resistance, mechanical strength, and corrosion resistance are critical, such as in electrical wiring protection and cable management for both indoor and outdoor applications.Q: Where can these conduit pipes be installed?

A: They are suitable for a range of settings including residential, commercial, and industrial environments throughout India and internationally, complying with IS 9537 and BS 4568 standards.Q: What is the process for ensuring the fire resistance and strength of the GI Conduit Pipe?

A: Each pipe undergoes a hot dip or pre-galvanization process and is manufactured from high-grade galvanized iron. The pipes meet rigorous standards, ensuring flame resistance and structural integrity, with tolerances maintained within 0.5 mm.Q: How does the bundle packaging with end caps benefit buyers and installers?

A: Bundling with end caps protects pipes from physical damage, dust, and contamination during storage and transport, ensuring they reach the site in optimal condition and reducing the risk of installation issues.Q: What are the usage scenarios for these conduits?

A: They are primarily used for electrical wiring protection and cable management, especially where high durability, fire safety, and corrosion protection are necessary, such as in industrial plants, commercial buildings, and infrastructure projects.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Electrical Conduit Pipes Category

HDPE Electrical Conduit Pipe

Price 50 INR / Meter

Minimum Order Quantity : 100

Product Type : Other, HDPE Electrical Conduit Pipe

Surface Treatment : Other, Smooth Exterior

Material : Other , HDPE (High Density Polyethylene)

Color : Black with Blue Stripes

Cable Transmission Kit

Price 50 INR / Meter

Minimum Order Quantity : 100

Product Type : Other, Cable Transmission Kit

Surface Treatment : Other, Galvanized, Polished

Material : Other , Steel, Aluminium

Color : Silver

PVC Electrical Conduit Pipe

Price 50 INR / Meter

Minimum Order Quantity : 100

Product Type : Other, Electrical Conduit Pipe

Surface Treatment : Other, Smooth

Material : Other , PVC (Polyvinyl Chloride)

Color : Grey

Electrical Conduit Pipe

Price 50 INR / Meter

Minimum Order Quantity : 100

Product Type : Other, Electrical Conduit Pipe

Surface Treatment : Other, Smooth Finish

Material : PVC

Color : Grey

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS