Flame Retardant Low Smoke Cables

Price 30 INR/ Meter

Flame Retardant Low Smoke Cables Specification

- Cable Type

- FRLS House Wiring, Power Cable

- Conductor Type

- Stranded or Solid

- Number of Conductor

- Single or Multi-Core (1C, 2C, 3C, up to 5C)

- Features

- Flame Retardant, Low Smoke, Halogen Free, High Fire Safety, Durable, Flexible, Non-toxic Emission

- Dielectiric Strength

- 2.5 kV (for 1 minute)

- Operating Temperature

- Up to 70C continuous

- Conductor Shape

- Round

- Diameter

- Depends on core count and size: ranges from 2 mm to 20 mm

- Tensile Strength

- Minimum 15 N/mm (insulation)

- Install Type

- Indoor / Outdoor, Surface / Concealed Installation

- Core Material

- Copper

- Rated Temperature

- -10C to +70C

- Insulation

- FRLS PVC

- Core Number

- Single core to multiple cores

- Usage & Applications

- Power Supply, Internal Wiring, Safety Zones, Fire Sensitive Areas

- Armored Material

- Optional: Steel Wire/Strip Armoring for enhanced protection

- Weight

- Variable as per size; 7-50 kg per coil

- Product Type

- Flame Retardant Low Smoke Cable

- Length

- Standard lengths: 100 meters; customizable on request

- Voltage

- Up to 1100V

- Insulation Material

- Flame Retardant Low Smoke Polyvinyl Chloride (FRLS PVC)

- Application

- Residential, Commercial, Industrial Wiring, Power Distribution, Public Spaces

- Conductor Material

- Copper

- Jacket Material

- FRLS PVC

- Storage Temperature

- -25C to +70C

- Shield Material

- No external shield (unshielded)

- Jacket Color

- Available in Red, Yellow, Blue, Black, Green, White

- Dimension (L*W*H)

- Varies with cable size and core count; standard coil dimensions

- Material

- Copper Conductor, FRLS PVC Insulation & Sheath

- Color

- Red, Yellow, Blue, Black, Green, White

- Size

- Range: 0.5 sq.mm to 400 sq.mm

- Oxygen Index

- Above 29% (enhanced safety)

- Lead-Free

- Yes

- Flame Test

- Passes flame retardance test as per IEC 60332

- Wire Identification

- Sequential marking and color-coding

- RoHS Compliance

- Yes

- Minimum Bending Radius

- 12 x Cable Diameter

- Packing Type

- Plastic-coiled/boxed

- Fire Resistance Duration

- Up to 90 minutes

- UV Resistance

- Yes

- Halogen Content

- Halogen Free

- Max. Short Circuit Temperature

- 160°C

- Moisture Resistance

- Yes

- Earth Continuity Conductor

- Available as per specification

- Smoke Density

- Low Smoke emission in case of fire

Flame Retardant Low Smoke Cables Trade Information

- Minimum Order Quantity

- 100 Meter

- Supply Ability

- 1000 Per Day

- Delivery Time

- 1 Days

About Flame Retardant Low Smoke Cables

These Flame Retardant Low Smoke Cables are insulated with special type FRLS PVC compound. These cables possess high oxygen and temperature index. Our provided cables are known for their low smoke emitting and toxic fumes suppressing properties. The properties of low smoke and acid gas generation maintain the visibility and accelerate the evacuation and rescue operation. The Flame Retardant Low Smoke Cables is suitable for use in high rise buildings, hospital, theaters, schools, and colleges etc. where the density of the people is high.

Low Smoke, Halogen Free Safety

FRLS cables drastically reduce smoke and toxic gas emissions in the event of fire, ensuring better visibility and safer evacuation. Their halogen-free construction eliminates the risk of corrosive and toxic fumes, making them ideal for public spaces, offices, and safety-sensitive installations.

Reliable Fire Protection and Resistance

Tested to IEC 60332 standards, these cables offer flame retardance and fire resistance up to 90 minutes. Their oxygen index above 29% means they support enhanced fire safety, making them suitable for critical locations like hospitals, schools, and industrial sites.

Durability and Compliance

With moisture resistance, UV protection, and a wide operating temperature range, FRLS cables are suitable for demanding indoor and outdoor conditions. Full RoHS and lead-free compliance ensures environmental safety while the robust construction guarantees long-term reliability.

FAQs of Flame Retardant Low Smoke Cables:

Q: How do Flame Retardant Low Smoke (FRLS) Cables enhance safety during a fire?

A: FRLS cables emit significantly less smoke and toxic gases compared to standard cables due to their low smoke, halogen-free insulation. This reduces the risk of suffocation and improves visibility, aiding safer evacuation and minimizing equipment damage during fires.Q: What are the main applications of these FRLS cables?

A: These cables are suitable for residential, commercial, and industrial wiring, power distribution, and installations in fire-sensitive or public areas such as hospitals, schools, and offices. They can be used for both surface and concealed wiring, indoors and outdoors.Q: When should I use FRLS cables over regular PVC cables?

A: Use FRLS cables when fire safety, low smoke emission, and non-toxicity are crucialparticularly in areas with high human occupancy or where vital equipment must be protected from corrosive gases during fires.Q: Where can these cables be installed and what installation types are supported?

A: FRLS cables are designed for versatility and can be installed indoors and outdoors, either on the surface or concealed within walls. They are suitable for power supply, internal wiring, safety zones, and fire-sensitive areas.Q: What is the process for ordering cables in custom lengths or configurations?

A: Standard lengths are 100 meters, but customization is available upon request. Customers can specify core count, size, color, and armoring requirements to suit their project needs. Distributors and manufacturers in India can assist with tailored orders.Q: How does the flame retardance and fire resistance of the cables meet safety standards?

A: These cables pass the IEC 60332 flame test and are rated for up to 90 minutes of fire resistance, ensuring compliance with stringent international and local fire safety standards for wiring systems.Q: What benefits do sequential marking and color-coding provide during installation?

A: Sequential marking and color-coding improve wire identification, streamline installation, and help with ongoing maintenance or troubleshooting, reducing errors and installation time in complex wiring projects.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber Cables Category

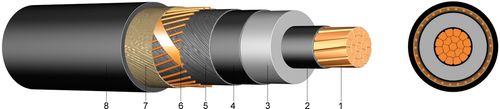

xlpe insulated high voltage cables

Price 30 INR / Meter

Minimum Order Quantity : 100

Weight : Varies depending on size and length; details available upon request.

Dimension (L*W*H) : Varies as per cable size and length; customizable on request.

Armored Material : Galvanized steel wire or tape, or aluminum wire (for single core).

Insulation : XLPE (cross linked polyethylene).

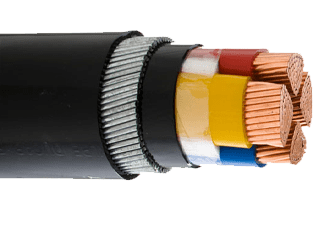

Durable Pvc Armoured Power Cables

Price 30 INR / Meter

Minimum Order Quantity : 100

Weight : Varies with cable size & length

Dimension (L*W*H) : As per size selection

Armored Material : Steel wire

Insulation : PVC Type A

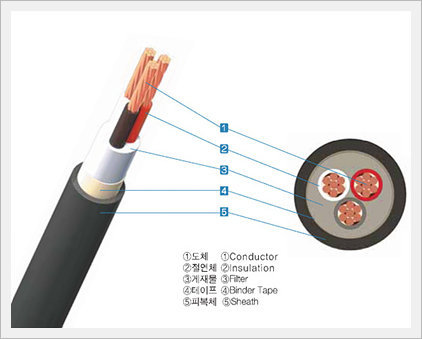

Xlpe Insulated Power Cable

Price 30 INR / Meter

Minimum Order Quantity : 100

Weight : Depends on conductor size and cable length

Dimension (L*W*H) : Varies as per cable size and specification

Armored Material : Galvanized Steel Wire/Steel Tape/Aluminum (optional)

Insulation : XLPE

Pvc Insulation Cable

Price 30 INR / Meter

Minimum Order Quantity : 100

Weight : Variable, depends on size/length

Dimension (L*W*H) : Custom / Standard, as per application

Armored Material : Nonarmored

Insulation : PVC Insulation

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS