Flame Retardant Industrial Cables

Price 30 INR/ Meter

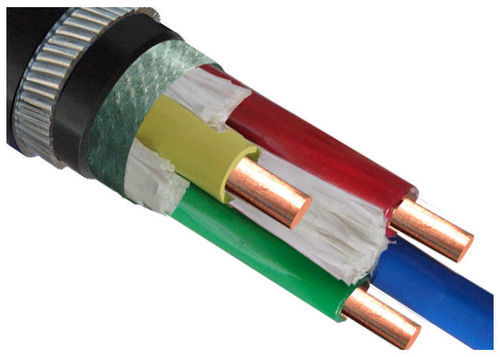

Flame Retardant Industrial Cables Specification

- Impedance

- Standard per IS:1554/IS:694

- Core Material

- Copper

- Install Type

- Indoor and Outdoor

- Weight

- Varies by length and size

- Dielectiric Strength

- 2.5 kV for 1 Min

- Rated Temperature

- Up to 85C

- Core Number

- 2, 3, or 4 core

- Features

- High flame retardant properties, Durable and flexible design, Resistant to oils, chemicals, and abrasions, Enhanced safety for industrial environments

- Armored Material

- Galvanized Steel

- Conductor Type

- Stranded

- Number of Conductor

- 2 to 4

- Cable Type

- Low Voltage Power & Control Cable

- Insulation

- PVC Flame Retardant

- Conductor Shape

- Circular

- Operating Temperature

- -10C to +85C

- Usage & Applications

- Industrial wiring, Panel wiring, Machine connection, Fire safety systems

- Diameter

- As per selected size

- Tensile Strength

- >300 N/mm

- Product Type

- Flame Retardant Industrial Cable

- Length

- Customizable up to 500 meters

- Voltage

- Up to 1100V

- Insulation Material

- PVC Flame Retardant

- Application

- Industrial power and control circuits, Fire safety installations

- Conductor Material

- Electrolytic Grade Annealed Copper

- Jacket Material

- Special Flame Retardant PVC

- Storage Temperature

- -10C to +60C

- Connector Color

- Black

- Shield Material

- Aluminium Foil and Copper Braiding

- Jacket Color

- Black

- Dimension (L*W*H)

- Varies as per cable selection

- Color

- Black

- Material

- Copper & PVC

- Size

- 1.5 sq.mm to 35 sq.mm

- Water Resistance

- Yes, for specified models

- Halogen Content

- Non-halogenated options available

- Minimum Bending Radius

- 12 x cable diameter

- Standards

- IS 694, IEC 60332-1

- Electrical Conductivity

- High conductivity copper >99.97% pure

- Smoke Emission

- Low smoke generation in fire

- Flame Retardance Test

- IEC 60332-1-2 compliant

- Packaging Type

- Rolls or drums as per order quantity

- UV Resistance

- Available on request for outdoor applications

Flame Retardant Industrial Cables Trade Information

- Minimum Order Quantity

- 100 Meter

- Supply Ability

- 1000 Per Day

- Delivery Time

- 1 Days

About Flame Retardant Industrial Cables

Our company is offering an extensive range of Flame Retardant Industrial Cables which are equipped with pure electrolytic copper conductor. The provided cables are single core cables which can be availed in different colors. This type of cables are known for their excellent good thermal stability which makes highly useful. The cable can sustain extreme temperature with much ease. As these Flame Retardant Industrial Cables are made with premium quality copper, ensuring superior conductivity and true value for money.

Comprehensive Fire Protection

Our industrial cables utilize flame retardant PVC and comply with stringent standards such as IS 694 and IEC 60332-1-2. This provides advanced fire containment and minimizes smoke emission, crucial for safeguarding industrial environments and ensuring compliance with modern safety regulations.

Adapted for Harsh Environments

Built to withstand rigorous conditions, these cables are resistant to oils, chemicals, mechanical stress, and ultraviolet exposure upon request. Their robust construction and armored options ensure reliability for both indoor and outdoor installations, making them a dependable choice for a range of industrial sectors.

Customizable and Versatile Solutions

Customers benefit from tailored solutions with cable lengths up to 500 meters and core configurations of 2, 3, or 4, suitable for diverse applications like machine connection, panel or industrial wiring, and fire safety circuits. Drums and roll packaging options align with varied order requirements, ensuring project flexibility.

FAQs of Flame Retardant Industrial Cables:

Q: How do flame retardant industrial cables enhance safety in industrial installations?

A: These cables are designed with flame retardant PVC insulation and comply with IS 694 and IEC 60332-1 standards, significantly reducing fire propagation and smoke generation during a fire. This minimizes risk to both personnel and equipment, making them ideal for safety-critical environments.Q: What is the process for selecting the appropriate cable size and configuration?

A: Selection depends on application requirements such as voltage (up to 1100V), number of cores (2 to 4), conductor size (1.5 sq.mm to 35 sq.mm), and installation type (indoor or outdoor). Consult technical documentation or supplier recommendations based on specific current rating, mechanical, and environmental conditions.Q: When should I consider non-halogenated or UV resistant cable options?

A: Opt for non-halogenated cables in installations where low smoke and minimal toxic gas emission are priorities, especially in enclosed or high-occupancy areas. UV resistant options should be requested for prolonged outdoor deployments to protect cables from ultraviolet degradation.Q: Where can these cables be used and what are their primary applications?

A: These cables are suitable for industrial power distribution, machine and panel wiring, control circuits, and fire safety systems. They are robust for indoor usage and, with UV resistance, applicable for outdoor installations in factories, industrial plants, or fire-prone zones.Q: What are the main benefits of using high conductivity copper as the conductor material?

A: Utilizing copper with a purity greater than 99.97% ensures excellent electrical conductivity, reducing energy loss and enhancing operational efficiency. This quality also promotes long-term cable reliability and supports higher tensile strength (>300 N/mm), important in industrial contexts.Q: How does the installation process account for cable flexibility and minimum bending radius?

A: With a durable, flexible design and a minimum bending radius of 12 times the cable diameter, these cables can be routed efficiently through tight spaces or complex pathways, reducing mechanical stress and prolonging operational life during installation and service.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Rubber Cables Category

Copper Pvc Armoured Power Cables

Price 30 INR / Meter

Minimum Order Quantity : 100

Color : Black

Size : 1.5 sqmm to 400 sqmm

Weight : Varies as per size and core

Dielectiric Strength : 3.5 kV for 5 minutes

Trs Rubber Cable

Price 30 INR / Meter

Minimum Order Quantity : 100

Color : Black

Size : 1.5 sqmm to 16 sqmm

Weight : As per size and length

Dielectiric Strength : 2.5 kV

Flame Retardant Welding Cable

Price 30 INR / Meter

Minimum Order Quantity : 100

Color : Black

Size : 16mm to 120mm

Weight : Varies by size and length

Dielectiric Strength : 2000V/min

Aluminium Unarmoured Xlpe Insulated Cables

Price 30 INR / Meter

Minimum Order Quantity : 100

Color : Standard Black, other colors available on request

Size : Range: 1.5 sqmm to 400 sqmm

Weight : Varies by size and length

Dielectiric Strength : Minimum 3.5 kV AC for 5 minutes

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free