33 11 1.1 Kv Pin, Stain, Post And Disc Type Porcelain Insulators

Price 30 INR/ Meter

33 11 1.1 Kv Pin, Stain, Post And Disc Type Porcelain Insulators Specification

- Rated Temperature

- -40°C to +60°C

- Usage & Applications

- Transmission and distribution of electrical power, supporting and insulating conductors

- Tensile Strength

- Greater than 10 kN (varies by insulator type)

- Operating Temperature

- -40°C to +60°C

- Diameter

- Depends on model type

- Dielectiric Strength

- High dielectric strength suitable for specified voltage

- Weight

- Ranges from 2 kg to 8 kg depending on type

- Install Type

- Pole mounting/Overhead line installation

- Features

- High mechanical strength, excellent electrical insulation, weather resistant, low maintenance

- Insulation

- Porcelain

- Product Type

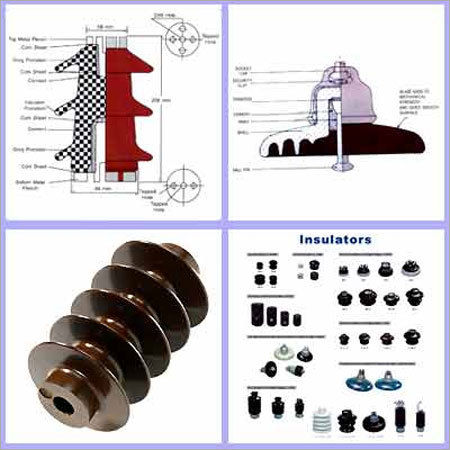

- Pin, Strain, Post and Disc Type Porcelain Insulator

- Length

- Standard

- Voltage

- 33/11/1.1 kV

- Insulation Material

- Porcelain

- Application

- Overhead transmission and distribution lines

- Storage Temperature

- -40°C to +70°C

- Dimension (L*W*H)

- Varies by insulator type

- Material

- Porcelain

- Color

- Brown/Gray

- Size

- Standard/As per IS specification

- Finish

- Glazed, smooth finish for outdoor use

- Power Frequency Withstand Voltage (Wet)

- 35 kV (11 kV insulator); 75 kV (33 kV insulator)

- Maintenance

- Routine inspection, cleaning if heavily soiled

- Standards

- IS 731 & IEC 60383

- Power Frequency Withstand Voltage (Dry)

- 40 kV (11 kV insulator); 85 kV (33 kV insulator)

- Mounting Type

- Horizontal/Vertical as per Installation

- Creepage Distance

- Minimum 320 mm (for 11 kV); 900 mm (for 33 kV) or as per requirements

- Type

- Pin, Strain, Post and Disc Insulator

- Type of Fitting

- GI/Metallic Fittings as per IS standard

- Thermal Expansion

- Low thermal expansion, unaffected by temperature fluctuations

- Resistant To

- UV, moisture, chemicals, mechanical shocks and vibrations

- Breakdown Voltage

- Exceeds rated class

- Impulse Withstand Voltage

- 75 kV (11 kV); 170 kV (33 kV)

33 11 1.1 Kv Pin, Stain, Post And Disc Type Porcelain Insulators Trade Information

- Minimum Order Quantity

- 100 Meter

- Supply Ability

- 1000 Per Day

- Delivery Time

- 1 Days

About 33 11 1.1 Kv Pin, Stain, Post And Disc Type Porcelain Insulators

We are proficient in offering a broad gamut of porcelain insulators including 33 11 1.1 Kv Pin, Stain, Post And Disc Type Porcelain Insulators. These insulators are coated with a special type of porcelain which does not allow the passage of heat and sound and the coating renders the ability to resist high temperature and current. Manufactured using top grade raw material under the stern guidance of professionals, these 33 11 1.1 Kv Pin, Stain, Post And Disc Type Porcelain Insulators can be availed from us at nominal price.

Engineered for High Voltage Application

Precision-crafted from premium porcelain, these insulators serve in 33 kV, 11 kV, and 1.1 kV lines, delivering high dielectric strength and mechanical reliability. Whether used as pin, strain, post, or disc types, their capability to withstand voltage surges and environmental extremes makes them a natural choice for modern power transmission and distribution systems.

Conformance to International Standards

Certified to both IS 731 and IEC 60383, these insulators fulfill all technical and safety criteria required for global utilities. Every unit undergoes thorough testing to satisfy power frequency and impulse withstand voltage requirements, ensuring uncompromised safety and durability throughout its service life.

Low Maintenance and Long-Lasting Performance

Thanks to their smooth, glazed exterior and highly inert porcelain composition, these insulators offer excellent resistance to UV rays, moisture, chemicals, and temperature fluctuations. Their low expansion rate and robust mechanical structure guarantee stable, low-maintenance operation in diverse environments.

FAQs of 33 11 1.1 Kv Pin, Stain, Post And Disc Type Porcelain Insulators:

Q: How are 33 11 1.1 kV porcelain insulators typically used in power distribution systems?

A: These insulators are commonly installed on overhead transmission and distribution lines to support and electrically isolate conductors. They prevent current leakage to poles or other support structures, ensuring safe and efficient power delivery.Q: What benefits do porcelain insulators offer compared to other materials?

A: Porcelain insulators provide high dielectric strength, low thermal expansion, and excellent resistance to environmental elements like UV rays, moisture, and chemicals. Their glazed surface reduces surface contamination and maintenance needs, making them especially suitable for outdoor use.Q: When should routine maintenance or inspection be performed?

A: Routine inspections are recommended at regular intervalstypically during scheduled power line maintenance. Cleaning may be required if the insulators are exposed to heavy pollution, dust, or salt deposits to ensure optimal electrical performance and safety.Q: Where can these insulators be mounted in electrical networks?

A: They can be mounted horizontally or vertically, depending on the installation requirements. They are suitable for pole mounting and overhead line installations across diverse environments, including urban, rural, and industrial settings.Q: What is the process for selecting the appropriate type of insulator?

A: Selection depends on the system voltage, mechanical load, environmental factors, and installation method. Consult system requirements and applicable standards (IS 731 or IEC 60383) to determine the correct type and specifications for pin, strain, post, or disc insulators.Q: How does the insulators design enhance safety and longevity?

A: The smooth, glazed finish resists surface contamination, while the porcelain construction ensures high mechanical strength and electrical insulation. Their robust design makes them impervious to mechanical shocks, temperature extremes, and chemical exposure, contributing to long service life and reliable operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Conductors Cable Category

LT PVC XLPE Power Control Cable

Price 30 INR / Meter

Minimum Order Quantity : 100

Armored Material : Galvanized Steel Wire/Strip or Aluminium

Material : Copper/Aluminium, PVC/XLPE

Dimension (L*W*H) : Based on cable size and length (customizable)

Install Type : Underground, Trunking, Tray, Surface

Copper Single Multicore Flexible Cable

Price 30 INR / Meter

Minimum Order Quantity : 100

Armored Material : Unarmored (standard)

Material : Copper, PVC

Dimension (L*W*H) : Custom as Per Requirement

Install Type : Tray, Conduits, Ducts, Surface & Concealed

Shielded Instrumentation Cable

Price 30 INR / Meter

Minimum Order Quantity : 100

Armored Material : Optional: Steel Wire Armour (SWA)

Material : PVC, Copper, Aluminum Mylar

Dimension (L*W*H) : Varies as per cable size

Install Type : Indoor / Outdoor fixed installations

Silicon EPR Rubber Cables

Price 30 INR / Meter

Minimum Order Quantity : 100

Armored Material : Optional – Steel Wire Armour (SWA) / Not Armored

Material : Silicon Rubber Insulated, EPR Jacketed, Copper Core

Dimension (L*W*H) : Depends on configuration and length

Install Type : Fixed, Flexible, Portable

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS