Shielded Instrumentation Cable

Price 30 INR/ Meter

Shielded Instrumentation Cable Specification

- Dielectiric Strength

- 2 kV for 1 minute

- Armored Material

- Optional: Steel Wire Armour (SWA)

- Usage & Applications

- Instrumentation, Data acquisition, Industrial automation

- Core Material

- Tinned Copper

- Insulation

- PVC Type A

- Number of Conductor

- 2 to 24 (as per specification)

- Impedance

- 100 Ohm 10%

- Install Type

- Indoor / Outdoor fixed installations

- Features

- Excellent shielding, Improved signal integrity, Flexible construction, Low capacitance, High resistance to electrical interference, Flame retardant

- Core Number

- 2 to 24

- Operating Temperature

- -20C to +70C

- Weight

- Variable (depends on specification)

- Cable Type

- Twisted Pair, Multi-core, Shielded

- Conductor Type

- Stranded

- Conductor Shape

- Round

- Rated Temperature

- -20C to +70C

- Diameter

- 6mm 15mm (depending on number of cores and size)

- Tensile Strength

- >1500 N

- Product Type

- Shielded Instrumentation Cable

- Length

- 100 meters (Custom lengths available)

- Voltage

- 300V

- Insulation Material

- PVC (Polyvinyl Chloride)

- Application

- Industrial instrumentation, Control panels, Process control, Data transmission

- Conductor Material

- Annealed Tinned Copper

- Jacket Material

- PVC

- Storage Temperature

- -30C to +75C

- Connector Color

- Silver (shield) / Multi-color cores

- Shield Material

- Aluminum Mylar + Tinned Copper Braid

- Jacket Color

- Black

- Dimension (L*W*H)

- Varies as per cable size

- Material

- PVC, Copper, Aluminum Mylar

- Color

- Black (jacket), Multicolor (cores)

- Size

- 0.5mm, 0.75mm, 1mm (Other sizes available)

- Oxygen Index

- >29%

- Pair Shielding

- Aluminum Mylar individually shielded pairs

- Packing Type

- Roll / Drum

- UV Resistance

- Yes

- Screen Coverage

- >90%

- Min Bending Radius

- 10 x Cable OD

- Flame Retardant Standard

- IEC 60332-1

- Halogen Free

- No

- Oil Resistant

- Yes

Shielded Instrumentation Cable Trade Information

- Minimum Order Quantity

- 100 Meter

- Supply Ability

- 1000 Per Day

- Delivery Time

- 1 Days

About Shielded Instrumentation Cable

Our patrons can purchase from us an excellent quality range of Shielded Instrumentation Cable. The provided cables are resistant to water, moisture, oil, and chemicals, therefore, massively used for transmission of electrical energy from one location to another. Designed with the aid of modern technology, this cable are of prime quality. Stringent quality tests are also conducted on the offered Shielded Instrumentation Cable to ensure its seamless performance and durability. Further, this gamut of cable is obtainable at competitive price from us.

Superior Shielding and Signal Integrity

Aluminum Mylar shields combined with a tinned copper braid deliver exceptional screening performance, boasting greater than 90% coverage. Each pair is individually shielded, which greatly reduces crosstalk and external electromagnetic interference, ensuring that data signals remain clear and accurate. This reliable shielding design is key in industrial environments with heavy electrical noise.

Versatile Applications and Flexible Installation

Engineered for both indoor and outdoor fixed installations, this cable handles a range of environments, from control panels to industrial automation. Its stranded, round conductors and flexible PVC jacket ease the installation process, even in tight spaces. Flame and oil resistance, plus UV protection, ensure robust performance wherever reliability and durability are needed.

High Standards for Safety and Performance

Conforming to IEC 60332-1 for flame retardancy and exhibiting a high oxygen index of over 29%, this instrumentation cable safeguards both assets and personnel. Dielectric strength up to 2kV for 1 minute and a tensile strength exceeding 1500 N underline its ability to withstand challenging operational demands. Available customization in lengths and conductor counts provide tailored solutions for any project.

FAQs of Shielded Instrumentation Cable:

Q: How does the cable maintain excellent signal integrity in industrial environments?

A: This cable utilizes individually shielded aluminum mylar pairs with tinned copper braid, offering over 90% screen coverage. Such shielding effectively reduces electromagnetic interference and crosstalk, helping data signals stay clear and reliable even amid heavy industrial noise.Q: What installation environments are suitable for this instrumentation cable?

A: Designed for both indoor and outdoor fixed installations, the cable is ideal in control panels, industrial automation, process control, and data transmission scenarios. Its oil resistance, UV protection, and flexibility make it practical for demanding industrial settings.Q: When should custom lengths or specific core counts be considered?

A: Custom lengths and various core counts (ranging from 2 to 24) should be specified when your installation requires adherence to unique distances, branch circuits, or particular signal routing needs, optimizing both performance and cost-efficiency.Q: Where can this cable be used to ensure optimal safety and compliance?

A: Its suitable for installation in facilities requiring strict flame retardancy standards, such as those following IEC 60332-1. Its high oxygen index adds safety under fire conditions, making it dependable for data rooms, factories, and automation centers.Q: What is the process for selecting the correct cable size and type from the available options?

A: To choose the right cable, assess your applications voltage (up to 300V), the number of signal channels (cores), and environmental factors like exposure to oil, UV, or mechanical stress. Use available sizes (0.5mm, 0.75mm, 1mm, or custom) and consider optional steel wire armour for extra protection if needed.Q: How does using this instrumentation cable benefit industrial automation processes?

A: Reliable shielding, low capacitance, and high dielectric strength make this cable ideal for accurate signal transmission, reducing error rates and system downtime in automated systems, which are vital for process integrity and operational efficiency.Q: What are the storage and operating conditions recommended for this cable?

A: The cable should be stored between -30C and +75C, with an operational temperature range from -20C to +70C. Proper storage and use within these parameters help preserve its mechanical integrity and performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Conductors Cable Category

LT PVC XLPE Power Control Cable

Price 30 INR / Meter

Minimum Order Quantity : 100

Usage & Applications : Industrial power control, energy distribution, outdoor and indoor control systems

Dielectiric Strength : 3.5 kV for 5 minutes

Material : Copper/Aluminium, PVC/XLPE

Insulation : PVC/XLPE

Silicon EPR Rubber Cables

Price 30 INR / Meter

Minimum Order Quantity : 100

Usage & Applications : Industrial, Power, Electrical Panels, Heaters, Chemical Plants

Dielectiric Strength : 20 kV/mm

Material : Silicon Rubber Insulated, EPR Jacketed, Copper Core

Insulation : Silicon Rubber

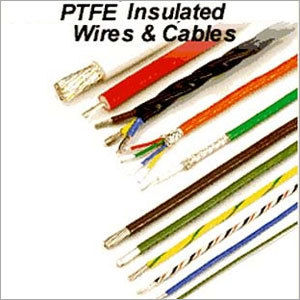

PTFE Insulated Wires & Cables

Price 30 INR / Meter

Minimum Order Quantity : 100

Usage & Applications : Instrumentation, High temperature environments, Labs, Switchgear, Control panels

Dielectiric Strength : 15 KV/mm

Material : PTFE, Copper

Insulation : PTFE

Copper Single Multicore Flexible Cable

Price 30 INR / Meter

Minimum Order Quantity : 100

Usage & Applications : Household, Industrial, Machinery, Control Panels

Dielectiric Strength : 2000V AC for 1 minute

Material : Copper, PVC

Insulation : PVC Insulation (Type A)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free