ACSR Conductors

ACSR Conductors Specification

- Product Type

- ACSR Conductors

- Application

- Electronic

- Protection Level

- IP65

- Rated Voltage

- 220 Volt (V)

- Color

- Black

- Warranty

- 1 Years

- Phase

- Three

ACSR Conductors Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 100 Pieces Per Week

- Delivery Time

- 7 Days

About ACSR Conductors

We are a leading manufacturer, exporter, and distributor of top quality AAC/AAAC /ACSR Conductors that are manufactured using high quality raw materials. These conductors are used for low and medium voltage applications across diverse industries. Our offered conductors are widely appreciated for their corrosion resistance, high strength, precise dimensions, light weight and low cost. AAC/AAAC /ACSR Conductors find their application in urban areas for overhead power transmission. Further, we offer these conductors in customized sizes and specifications as per our clients' requirements.

Other Details:

AAC / AAAC / ACSR Conductors

We are manufactures of a wide range of conductors that includes AAC/ACSR Conductors, All Aluminium Alloy Conductors, Aluminium Conductor, Aluminized Steel Reinforced (ACASR) Conductors, Aluminium Alloy Conductors Steel Reinforced (AACSR) Conductors, Other Special Conductors, as per Customer's Reruirement

Applications

AAAC: Used as bare overhead conductor for primary and secondary distribution. Designed utilizing high strength aluminium alloy to achieve a high strength-to-weight ratio; affords better sag characteristics. Aluminium alloy gives AAAC higher resistance to corrosion than ACSR.

AAC-ACSR: Used as bare overhead transmission cable and as primary and secondary distribution cable. ACSR offers optimal strength for line design. Variable steel core stranding enables desired strength to be achieved without sacrificing capacity.

AACSR: Used as bare overhead transmission cable and as primary and secondary distribution cable. AACSR offers optimal strength for line design. Variable steel core stranding enables desired strength to be achieved without sacrificing capacity.

AAC: Stranded 1350 aluminium conductors shown in this section of data are classified, as follows:

Class AA: For bare conductors usually used in overhead lines

Class A: For conductors to be covered with weather-resistant materials and for bare conductors where greater flexibility is required

Class B: For conductors to be insulated with various materials and for conductors indicated under Class A where greater flexibility is required

Class C: For conductors where greater flexibility is required

|

DIMENSIONS & WEIGHTS

|

|||||||||||||||||||||||

|

ALL ALUMINIUM CONDUCTOR (A.A. C)

|

|||||||||||||||||||||||

|

|||||||||||||||||||||||

|

Code Name

|

|||||||||||||||||||||||

|

Sq. mm.

|

Sq.mm.

|

Ohms/Km

|

Amp.

|

Amp.

|

NO/Dia

|

(mm)

|

Sq.mm

|

Kg/Km

|

Kg.

|

||||||||||||||

|

-

|

7.5

|

12.23

|

2.33

|

42

|

80

|

7/1.50

|

4.50

|

12.37

|

34

|

220

|

|||||||||||||

|

ROSE

|

13

|

20.89

|

1.36

|

75

|

130

|

7/1.96

|

5.88

|

21.12

|

58

|

385

|

|||||||||||||

|

GNAT

|

16

|

26.56

|

1.07

|

85

|

140

|

7/2.21

|

6.63

|

26.85

|

73

|

485

|

|||||||||||||

|

-

|

20

|

32.37

|

0.88

|

100

|

160

|

7/2.44

|

7.32

|

32.73

|

89

|

580

|

|||||||||||||

|

LADYBIRD

|

25

|

42.33

|

0.67

|

120

|

190

|

7/2.79

|

8.37

|

42.80

|

117

|

737

|

|||||||||||||

|

ANT

|

30

|

52.26

|

0.54

|

135

|

215

|

7/3.10

|

9.30

|

52.85

|

114

|

892

|

|||||||||||||

|

FLY

|

40

|

62.86

|

0.45

|

155

|

240

|

7/3.40

|

10.20

|

63.55

|

174

|

1,051

|

|||||||||||||

|

BLUEBOTTEL

|

45

|

72.84

|

0.39

|

174

|

266

|

7/3.66

|

10.95

|

73.65

|

201

|

1,203

|

|||||||||||||

|

EARWIG

|

48

|

77.70

|

0.37

|

180

|

275

|

7/3.78

|

11.34

|

78.55

|

215

|

1,272

|

|||||||||||||

|

GRASS-HOPPER

|

50

|

83.13

|

0.34

|

190

|

290

|

7/3.91

|

11.73

|

84.05

|

230

|

1,356

|

|||||||||||||

|

CLEGG

|

60

|

94.56

|

0.30

|

207

|

313

|

7/4.17

|

12.51

|

95.60

|

261

|

1,523

|

|||||||||||||

|

WASP

|

65

|

104.80

|

0.27

|

220

|

330

|

7/4.39

|

13.17

|

106.00

|

290

|

1,673

|

|||||||||||||

|

-

|

80

|

132.20

|

0.22

|

255

|

375

|

19/3.00

|

15.00

|

134.30

|

369

|

1,228

|

|||||||||||||

|

-

|

90

|

148.50

|

0.19

|

280

|

405

|

19/3.18

|

15.90

|

150.90

|

414

|

2,484

|

|||||||||||||

|

CATERPILLER

|

110

|

183.00

|

0.16

|

303

|

466

|

19/3.53

|

17.65

|

186.00

|

511

|

2,985

|

|||||||||||||

|

DIMENSIONS & WEIGHTS

|

||||||||||||||

|

ALL ALUMINIUM CONDUCTOR STEEL REINFORCED (A.C.S.R.)

|

||||||||||||||

|

||||||||||||||

|

Code Name

|

Equivalent

|

Equivalent nominal Aluminium

|

Calculated resistance at 20 0 C d.c.

|

Current rating in still air

|

Standing & Wire diameter (mm)

|

Overall cond. dia

|

Approximate Weight Kg/Km

|

Ultimate tensile Strength

|

||||||

|

Aluminium

|

Steel

|

|||||||||||||

|

Sq. mm. |

Sq.mm. |

Ohms/Km |

Amp. |

NO/Dia |

NO/Dia |

(mm) |

A1 |

Steel |

Total |

Kg. |

||||

|

SQUIRREL

|

13

|

20.71

|

1.3740

|

76

|

6/2.11

|

1/2.11

|

6.33

|

58

|

27

|

85

|

711

|

|||

|

GOPHER

|

16

|

25.91

|

1.0980

|

85

|

6/2.35

|

1/2.36

|

7.09

|

72

|

34

|

106

|

952

|

|||

|

WEASEL

|

20

|

31.21

|

0.9116

|

95

|

6/2.59

|

1/2.59

|

7.77

|

87

|

41

|

128

|

1,136

|

|||

|

FERRET

|

25

|

41.87

|

0.6795

|

115

|

6/3.00

|

1/3.00

|

9.00

|

116

|

55

|

171

|

1,503

|

|||

|

RABBIT

|

30

|

52.21

|

0.5449

|

135

|

6/3.35

|

1/3.35

|

10.05

|

145

|

69

|

214

|

1,860

|

|||

|

MINK

|

40

|

62.32

|

0.4565

|

165

|

6/3.66

|

1/3.66

|

11.00

|

173

|

82

|

255

|

2,207

|

|||

|

BEAVER

|

45

|

74.07

|

0.3841

|

176

|

6/6.99

|

1/3.99

|

12.00

|

206

|

98

|

304

|

2,613

|

|||

|

RACOON

|

48

|

77.83

|

0.3656

|

180

|

6/4.09

|

1/4.09

|

12.30

|

215

|

103

|

318

|

2,746

|

|||

|

OTTER

|

50

|

82.85

|

0.3434

|

185

|

6/4.22

|

1/4.22

|

12.60

|

230

|

109

|

339

|

2,923

|

|||

|

CAT

|

55

|

94.21

|

0.3020

|

195

|

6/4.50

|

1/4.50

|

13.50

|

261

|

124

|

385

|

3,324

|

|||

|

DOG

|

65

|

103.6

|

0.2745

|

205

|

6/4.72

|

7/1.57

|

14.20

|

288

|

106

|

394

|

3,299

|

|||

|

LEOPARD

|

80

|

129.7

|

0.2193

|

275

|

6/5.28

|

7/1.76

|

15.85

|

360

|

133

|

493

|

4,137

|

|||

|

COYOTE

|

80

|

128.5

|

0.2214

|

260

|

26/2.54

|

7/1.90

|

16.86

|

365

|

156

|

521

|

4,638

|

|||

|

TIGER

|

80

|

128.1

|

0.2221

|

265

|

30/2.36

|

7/2.36

|

16.50

|

363

|

241

|

604

|

5,758

|

|||

|

WOLF

|

95

|

154.3

|

0.1844

|

305

|

30/2.59

|

7/2.59

|

18.10

|

436

|

291

|

727

|

6,880

|

|||

|

LYNX

|

110

|

179.0

|

0.1589

|

335

|

30/2.79

|

7/2.79

|

19.60

|

507

|

338

|

845

|

7,950

|

|||

|

PANTHER

|

130

|

207.0

|

0.1375

|

370

|

30/3.00

|

7/3.00

|

21.00

|

586

|

390

|

976

|

9,127

|

|||

|

LION

|

140

|

232.5

|

0.1223

|

405

|

30/3.18

|

7/3.18

|

22.30

|

659

|

438

|

1097

|

10,210

|

|||

|

BEAR

|

160

|

258.1

|

0.1102

|

430

|

30/3.35

|

7/3.35

|

22.90

|

734

|

485

|

1219

|

11,310

|

|||

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Electrical Conductors Category

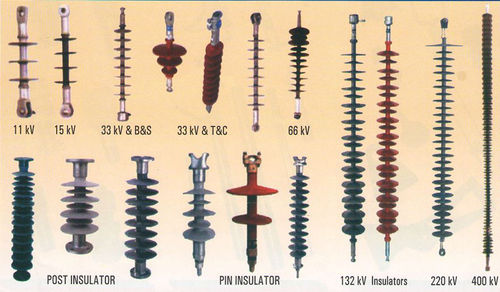

Polymer Insulators

Weight : Varies depending on type and size

Application : Power transmission and distribution lines

Feature : High voltage insulation weather resistance

Insulation Material : Polymer

Operating Temperature : Suitable for various climates

Surface Finish : Smooth weatherresistant polymer

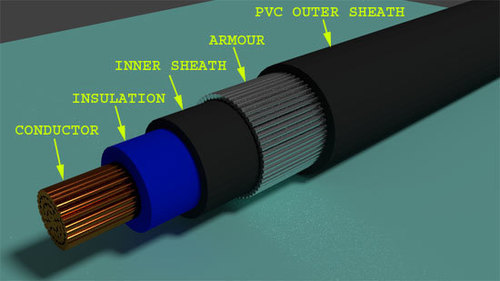

Electrical Conductors

Weight : Depends on size and length; typically heavy due to armoring

Application : Electrical power transmission

Feature : Armored for protection

Insulation Material : PVC (Polyvinyl Chloride)

Operating Temperature : Depends on insulation typically 15C to +70C

Surface Finish : PVC outer sheath with smooth finish

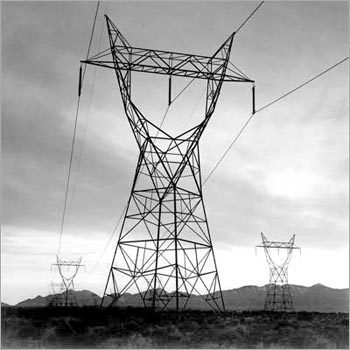

Coyote ACSR Conductor

Weight : Depends on conductor size

Application : Electrical transmission lines

Feature : Composite core for increased aluminum percentage (28%)

Insulation Material : None (bare conductor)

Operating Temperature : Suitable for outdoor conditions

Surface Finish : Smooth metallic finish

Dc Glands

Weight : Varied depending on size

Application : Cable management and protection

Feature : Waterproof durable corrosionresistant

Insulation Material : Rubber or Plastic (for sealing purposes)

Operating Temperature : Typically 40C to 100C

Surface Finish : Nickelplated for corrosion resistance

Send Inquiry

Send Inquiry